“Great discoveries and improvements invariably involve the cooperation of many minds.” – A.G. Bell

As a team of scientists, problem solvers, engineers, and strategic thinkers, Oxyphen is passionate about partnering with our customers to create high-value solutions that bring their product design or concept to life. By leveraging Oxyphen’s decades of experience and expertise, our partners can gain a competitive advantage by advancing innovation in markets such as automotive, electronics, industrial, and life sciences.

Through our membrane development, design, and quality manufacturing expertise, we combine different track-etched membrane technologies with plastic molds or adhesives to create turnkey solutions. In addition to customizing our laminated and unlaminated membranes with various hydrophilic, hydrophobic, or oleophobic treatments to increase water flow, wetting abilities, and water entry pressure of the membrane, we can easily adapt pore density, pore size, thickness, and shapes to your specific application.

We want to hear more about your ideas, next-generation developments, and what venting or filtration challenges may be hindering your progress. Let us partner with you to help you get where you want to be.

Highlighted Case Study

Electronic Textiles

Oxmotex AG is a research and development company dedicated to electroosmotic vapor and fluid transport, who developed revolutionary proprietary technology for electronically controlled moisture transport in membranes and textiles. As they looked to create a new innovative technology that would provide active electronically driven moisture transport, they came to Oxyphen for a track-etched membrane solution that would be responsive to changing climates, transport moisture beyond normal sweat rates, and be comfortable for the wearer.

Related Resources

Viral Filtration Efficiency (VFE) Certificate

Final test report from Nelson Labs for Viral Filtration Efficiency (VFE) at an Increased Challenge Level. Also available is the Bacterial Filtration Efficiency (BFE) report.

Bacterial Filtration Efficiency (BFE) Certificate

Final test report from Nelson Labs for Bacterial Filtration Efficiency (BFE) at an Increased Challenge Level. Also available is the Viral Filtration Efficiency (VFE) report.

Rollstock Membrane Product Brochure

Learn more about Oxyphen rollstock track-etched membrane material for in-house and large-scale manufacturing integration, which can be produced laminated or unlaminated, converted into different lengths, and surface treated upon request.

Register for our On-Demand Webinar

Delivering Precision & Control: An Introduction to Track-Etched Membrane Technology

Related Products

OxyPad® Self-Adhesive Pads

OxyPad® membrane pads, which are easily integrated inside or outside your housing design, promote consistent pressure equalization and protection against water, dust, and other harmful particulates.

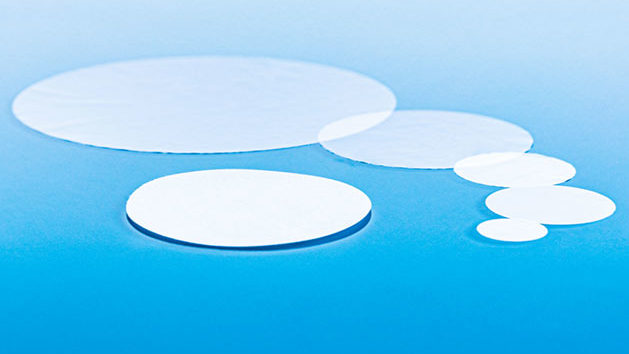

OxyDisc® Die-Cut Membrane Discs

OxyDisc® die-cut membrane discs can be easily mounted and produced using either hydrophobic or hydrophilic membranes for a variety of filtration or venting application requirements.

OxySeal® Pressure Compensation Units

OxySeal® pressure compensated venting plugs, which are available with hydrophobic or oleophobic treated membranes, can prevent the ingress of liquid, water, dust, dirt, salt, and other contaminants.

Membrane Technologies Available

Technologies

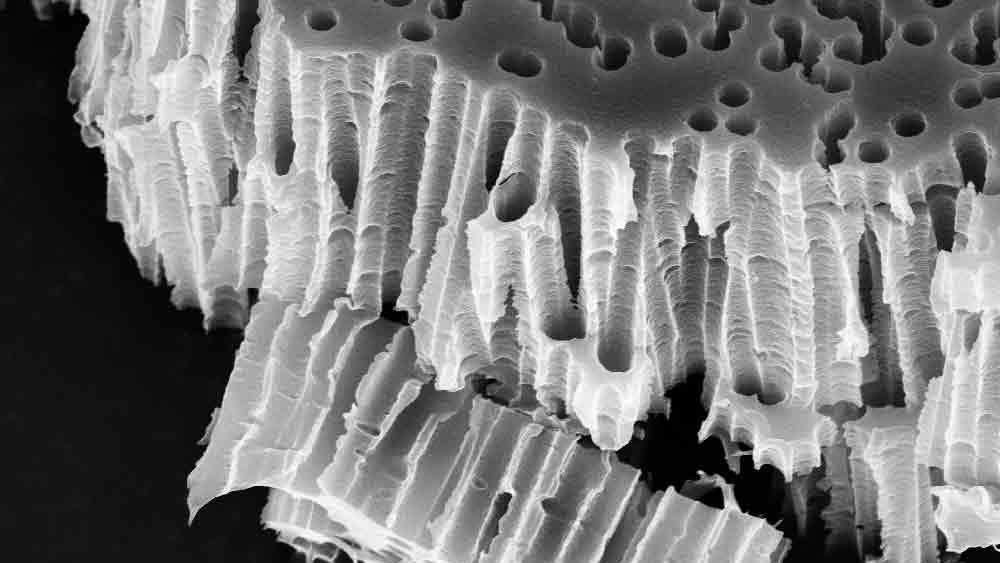

Unique-Mem® Unlaminated Track-Etched Membranes

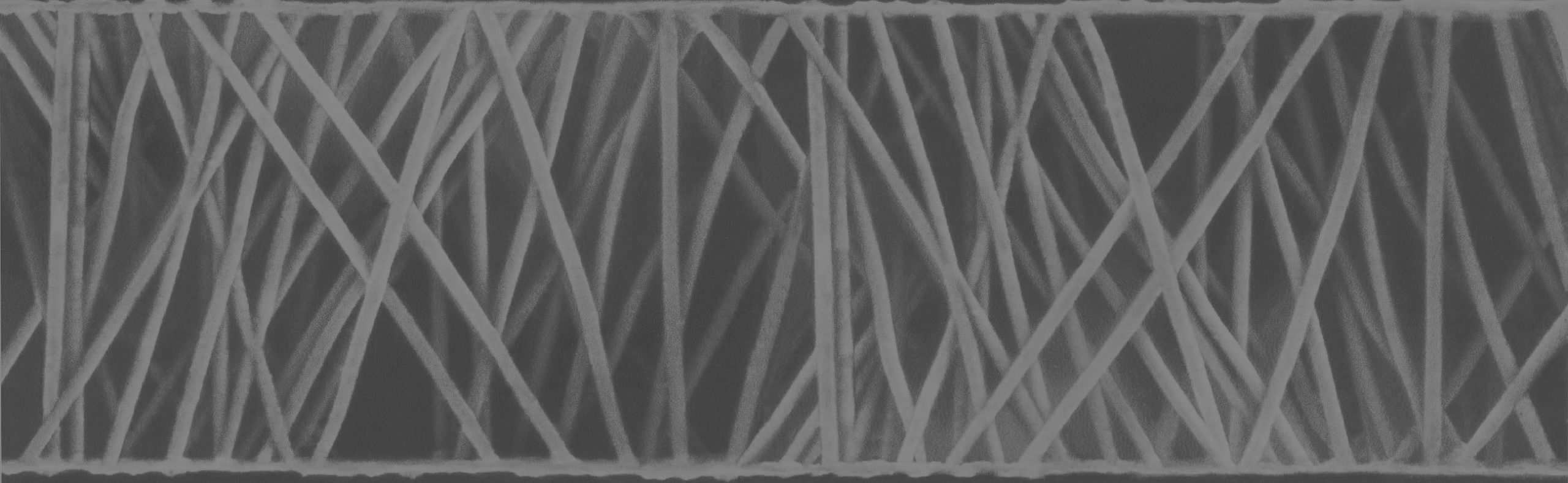

Unique-Mem® track-etched membranes, available as hydrophilic or hydrophobic, are characterized by cylindrical shaped pores penetrating the membrane in different angles. They have a smooth flat surface and well-defined flow rates.

Technologies

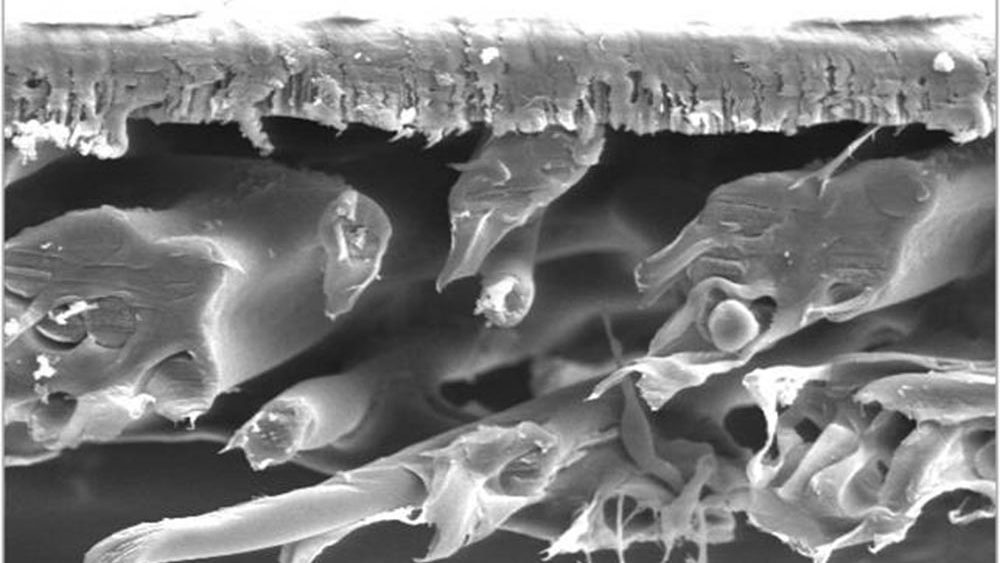

RoTrac® Laminated Track-Etched Membranes

RoTrac® track-etched membranes are Unique-Mem® membranes that are supported with non-wovens (PP or PET) to create a more robust membrane. They are available as either hydrophilic or hydrophobic membranes.

Technologies

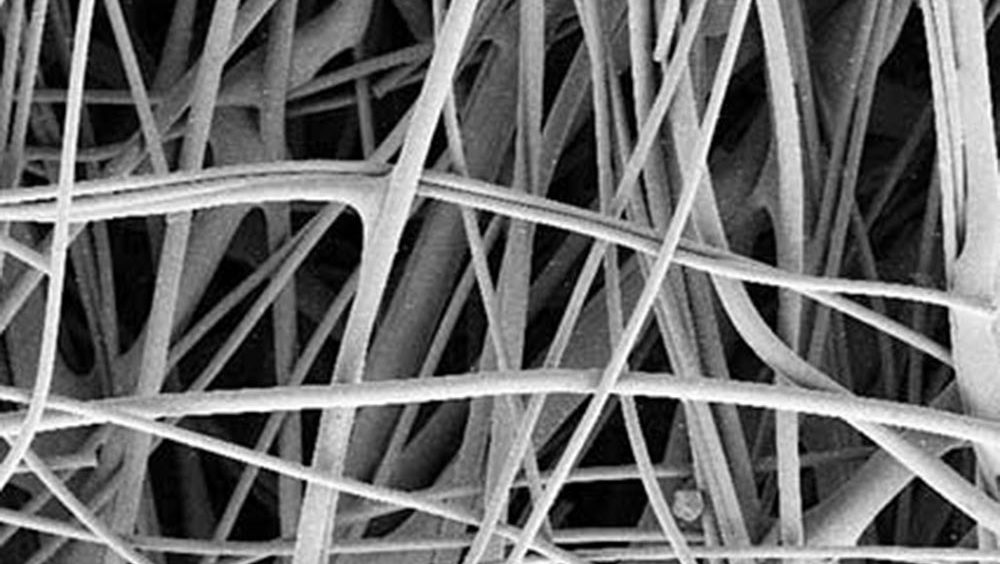

Fiber-Based Membranes

Fiber-based membranes are surface modified using a super-hydrophobic coating to repel water and other liquids while still allowing maximum airflow.

Contact Us

Interested in speaking with one of our track-etched membrane experts?