Oxyphen partners with customers across the automotive, healthcare, and industrial markets to develop components and assemblies for specific venting and filtration applications. When partnering with our team of material science experts, you can leverage our wide spectrum of products to bring your next generation concept or design to life.

Rollstock Membrane

Perfect for High-Volume & Integrated Mounting Applications

Oxyphen’s track-etched Rollstock membrane can be laminated, unlaminated, or fiber-based – supplied from polyester (PET), polycarbonate (PC), or custom based raw materials for in-house and large-scale production.

OxyPad® Self-Adhesive Pads

Protect Your Electronic Housings Against Water & Dust

OxyPad® membrane pads, which are easily integrated inside or outside your housing design, promote consistent pressure equalization and protection against water, dust, and other harmful particulates.

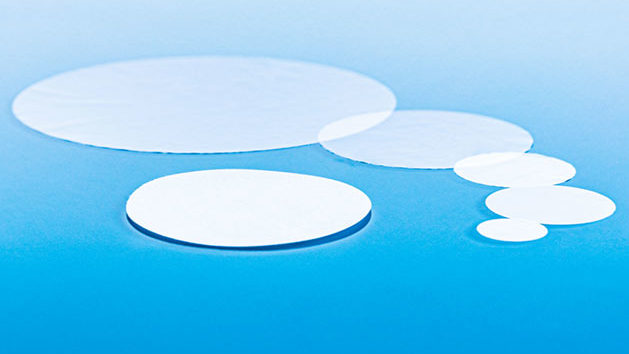

OxyDisc® Die-Cut Membrane Discs

Easily Assembled Standard & Customizable Shapes

OxyDisc® die-cut membrane discs can be easily mounted via heat-staking or ultrasonic welding. They are produced using oleophobic, hydrophobic, or hydrophilic surface properties for a variety of filtration and venting application requirements.

OxySeal® Pressure Compensation Units

Plug-in Venting Solutions for Liquid Retention & Gas Exchange

OxySeal® pressure compensated venting plugs, which are available with hydrophobic or oleophobic treated membranes, can prevent the ingress of liquid, water, dust, dirt, salt, and other contaminants.

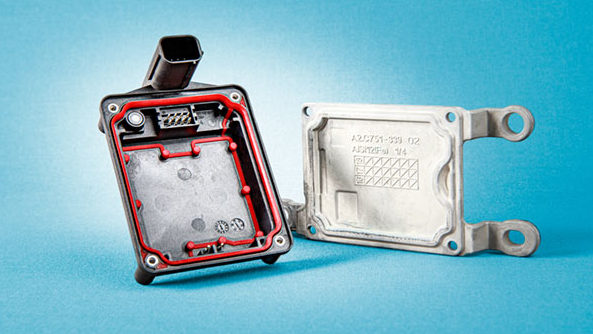

Assemblies & Modules

Single-Source Components & Assemblies

To meet specific product solution requirements within the life-science and automotive spaces, Oxyphen partner with leading OEMs to develop and produce highly tailored components and assemblies for specific applications.

Customized Solutions

Track-Etched Membranes Tailored to Your Needs

Oxyphen consists of a team of scientists, problem solvers, engineers, and strategic thinkers who are passionate about creating high-value solutions that bring customer’s product designs or concepts to life.

Contact Us

Interested in speaking with one of our track-etched membrane experts?