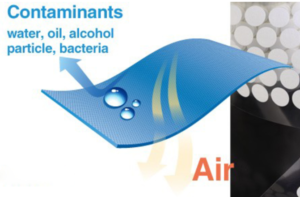

Various patient monitoring medical devices need protection from fluids and/or bacteria and viruses. In addition, these devices often must balance different pressures as required by the applications. Track-etched membranes are a key component as they show a high resistance towards pressure changes and are therefore an ideal solution for applications with high movement of membrane and unlimited incremental pressure changes. Oxyphen membranes do not show elongation.

Due to their smooth surface, track-etched membranes are a perfect surface filter with reversible (backflush) and self-cleaning functionality for hydrophobic venting applications.

Highlighted Case Study

Electronic Textiles

Oxmotex AG is a research and development company dedicated to electroosmotic vapor and fluid transport, who developed revolutionary proprietary technology for electronically controlled moisture transport in membranes and textiles. As they looked to create a new innovative technology that would provide active electronically driven moisture transport, they came to Oxyphen for a track-etched membrane solution that would be responsive to changing climates, transport moisture beyond normal sweat rates, and be comfortable for the wearer.

Related Resources

Viral Filtration Efficiency (VFE) Certificate

Final test report from Nelson Labs for Viral Filtration Efficiency (VFE) at an Increased Challenge Level. Also available is the Bacterial Filtration Efficiency (BFE) report.

Bacterial Filtration Efficiency (BFE) Certificate

Final test report from Nelson Labs for Bacterial Filtration Efficiency (BFE) at an Increased Challenge Level. Also available is the Viral Filtration Efficiency (VFE) report.

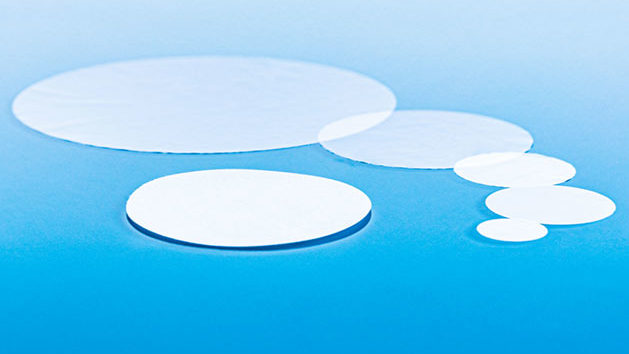

OxyDisc® Product Brochure

Learn more about OxyDisc® die-cut membrane discs that can be produced using either hydrophobic or hydrophilic membranes and easily handled and mounted using multiple assembly options to suit a variety of industries.

Register for our On-Demand Webinar

Delivering Precision & Control: An Introduction to Track-Etched Membrane Technology

Related Products

Rollstock Membrane

Ideally suited for in-house and large-scale manufacturing applications, Oxyphen’s track-etched rollstock membrane can be laminated, unlaminated, or fiber-based – supplied from polyester (PET) or polycarbonate (PC) high quality raw materials.

OxyPad® Self-Adhesive Pads

OxyPad® membrane pads, which are easily integrated inside or outside your housing design, promote consistent pressure equalization and protection against water, dust, and other harmful particulates.

OxyDisc® Die-Cut Membrane Discs

OxyDisc® die-cut membrane discs can be easily mounted and produced using either hydrophobic or hydrophilic membranes for a variety of filtration or venting application requirements.

Membrane Technologies Available

Technologies

Unique-Mem® Unlaminated Track-Etched Membranes

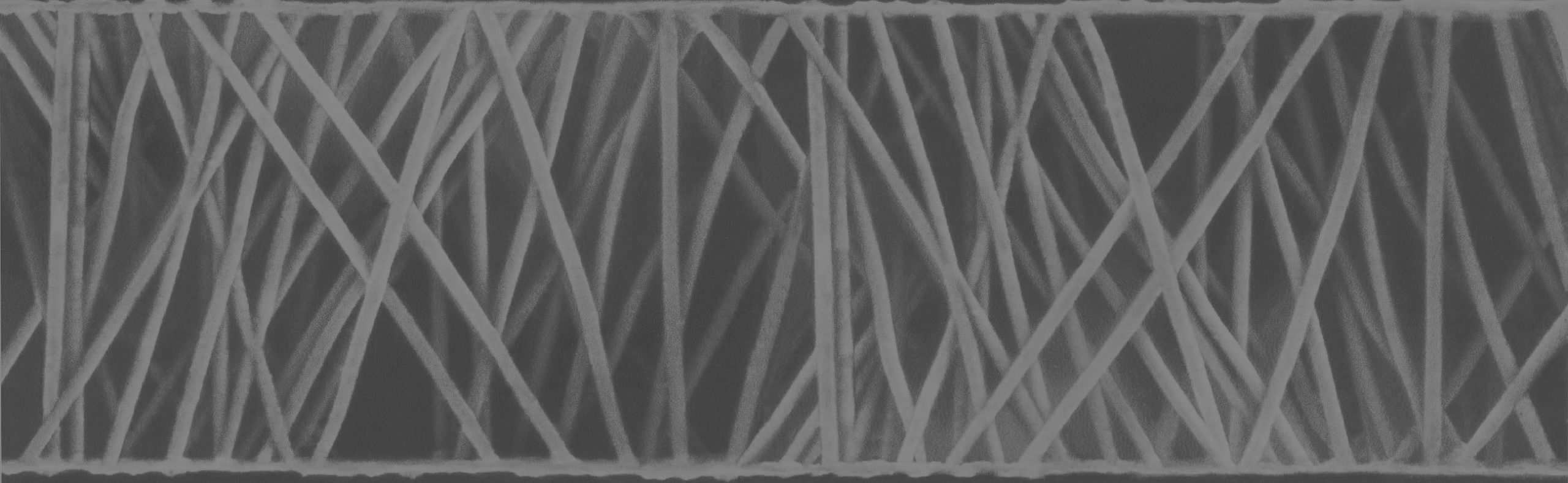

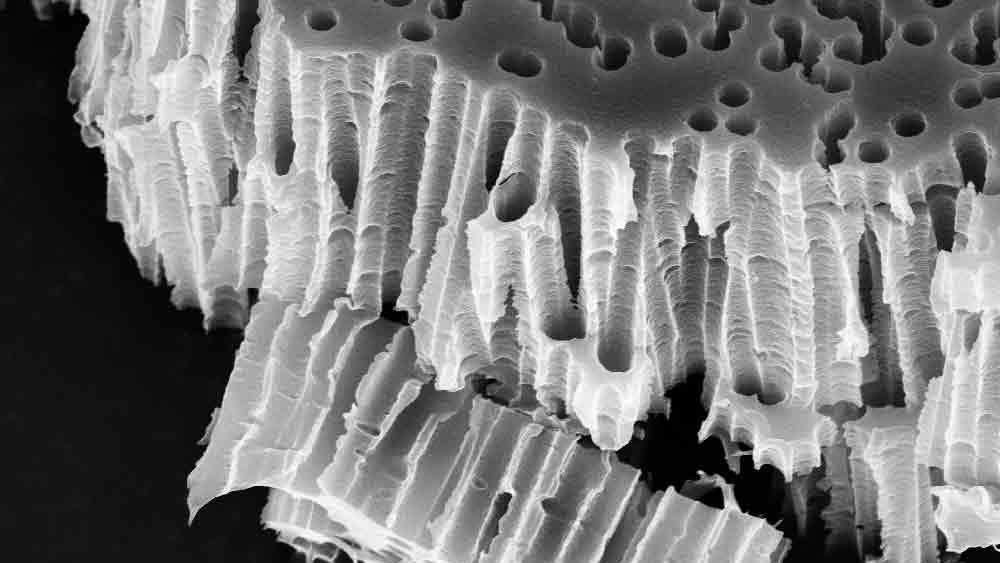

Unique-Mem® track-etched membranes, available as hydrophilic or hydrophobic, are characterized by cylindrical shaped pores penetrating the membrane in different angles. They have a smooth flat surface and well-defined flow rates.

Technologies

RoTrac® Laminated Track-Etched Membranes

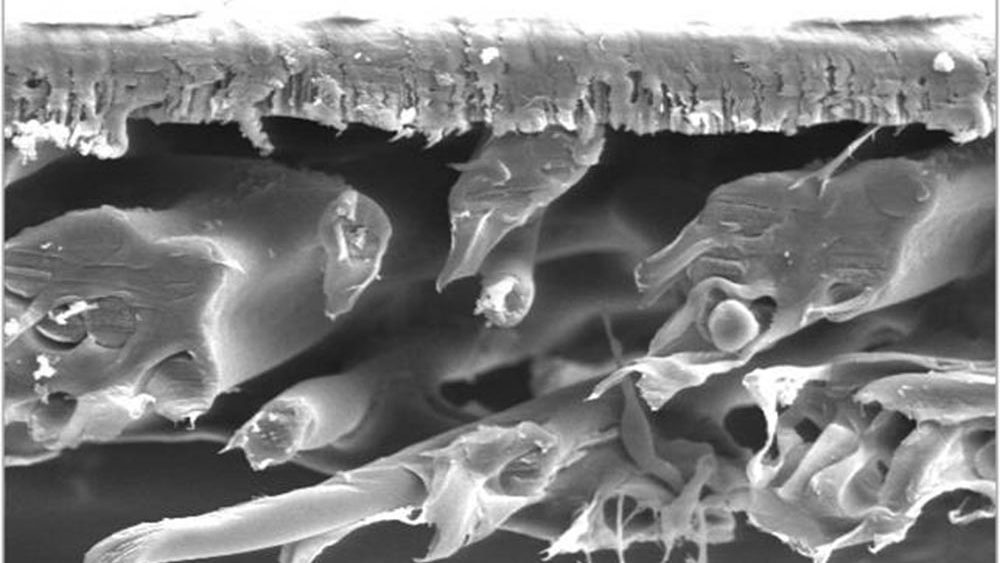

RoTrac® track-etched membranes are Unique-Mem® membranes that are supported with non-wovens (PP or PET) to create a more robust membrane. They are available as either hydrophilic or hydrophobic membranes.

Contact Us

Interested in speaking with one of our track-etched membrane experts?