Quality Management

At Oxyphen, it is our mission to be your reliable partner in quality and sustainability. By working closely with our customers, we can develop a highly tailored membrane that you can depend on.

Our focus on total Quality Management can be seen in our management processes, which are documented and regulated in our Integrated Management System. In addition, we maintain detailed process flows as described in our Quality Management Handbook.

All resources are in compliance with DIN EN ISO 9001 and IATF 16949:2016. We are also in the process of obtaining ISO 14001 and ISO 13485 certification – scheduled for 2024.

Quality Assurance

At Oxyphen, Quality Assurance is at the foundation of our culture. We hold not only our own employees to this standard, but also our network of suppliers. Whether it be 100,000 or over a billion pieces, our team is committed to ensuring each track-etched membrane part is built to the highest quality standard available on the market.

Documented In-process controls & final inspection procedures

Continuous improvement process for higher performance levels & cost reductions

In compliance with applicable statutory provisions, standards, laws, regulations and guidelines

Highly skilled, trained and motivated employees with extensive quality, safety and environmental awareness

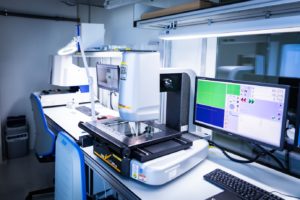

Process Validation

Oxyphen’s membrane manufacturing processes are independently validated, step-by-step, at both production plants to ensure the assembly process is highly repeatable and low risk for our customers. These guidelines are always determined through extensive consultation with our customers.

For more complex processes in need of newly engineered tools or equipment, validation procedures follow the guidelines as outlined by IQ (installation qualification), OQ (operational qualification) and PQ (Performance Qualification). Specific requests for process validations are performed in alignment with the customer and in accordance with applicable regulations. Examples include sterilization validation following ISO 11137 or biological testing in accordance with USP or FDA regulation using DIN ISO 17025 accredited external partners.

Oxyphen also maintains the capability to include the production of a clean room environment (DIN ISO Class 7 for Life Science products) for validation purposes.

Product Validation

In alignment with our process validation guidelines, we also work with our customers to develop and implement protocols for product validation, including initial sample inspection reports. Serving the automotive and life science markets, all products are produced in accordance with IATF 16949, AIAG and VDA as well as the respective regulations for the Life Science market listed below.

Standard test methods include:

- Membrane performance tests:

- Water entry pressure (WEP)

- Air flow rate

- Burst pressure

- Pore size and pore density

- Water flow rate

- Surface microscopy

- Dimensional accuracy test both manual and automated in process control for specific products

- Statistical tests

Specific test regimes regarding e.g. biological tests in acc. with DIN ISO 10993 or USP/FDA regulations as well as specific test for automotive devices for IP classification acc. DIN 400050, electrical components in acc. with LV124/ISO 16750-5 and climate resistance acc. to ISO 16750-4 are aligned with the customer on each project scope.

Contact Us

Would you like to speak to one of our nuclear track membrane experts?