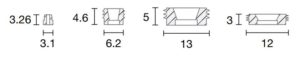

To prevent the ingress of oily liquids, water, dust, dirt, salts, or other contaminants into your electronics, OxySeal® pressure compensation units can be deployed as an easy plug-and-play venting solution for housings having inverted cylindrical openings. Using hydrophobic track-etched membranes, these injection molded plugs – which can also be treated to be oleophobic – are composed with a thermoplastic elastomer seal that does not require an additional anchor or fastener to ensure a tight fit.

Beyond its standard portfolio, OxySeal® can also be fully customizable. This includes selection of the dimensions, shape, and membrane properties specific to your application’s requirements.

Highlighted Case Study

Automotive Tail-Light Venting

A manufacturer of automotive lighting equipment reached out to Oxyphen to develop and design a hydrophobic membrane venting solution that would address their needs around ingress protection, adequate airflow to prevent condensation, customized temperature stability requirements, and meet PFOA-free properties without compromising liquid repellence performance.

Related Resources

OxySeal® Product Brochure

Learn more about OxySeal® pressure compensation units that are designed to be a plug & play solution for easy integration into existing product assemblies while protecting from any environmental impact.

EV Battery Safety Vents Application Brochure

Learn more about Oxyphen’s hydrophobic all-in-one solution that protects critical internal components from the ingress of liquid, dust, dirt, and other contaminants while also having the ability to burst at predefined overpressures to prevent potential explosions from taking place in the event of thermal runaway.

Automotive Lighting Application Brochure

Learn more about Oxyphen’s ultra-hydrophobic fiber-based membrane vents that provide a high airflow while also preventing liquid, fine dust and particles, and humidity from entering the lighting system.

Register for our on-demand Webinar

For precision and control: An introduction to track-etched membrane technology

Related Products

Rollstock Membrane

Ideally suited for in-house and large-scale manufacturing applications, Oxyphen’s track-etched rollstock membrane can be laminated, unlaminated, or fiber-based – supplied from polyester (PET) or polycarbonate (PC) high quality raw materials.

OxyPad® Self-Adhesive Pads

OxyPad® membrane pads, which are easily integrated inside or outside your housing design, promote consistent pressure equalization and protection against water, dust, and other harmful particulates.

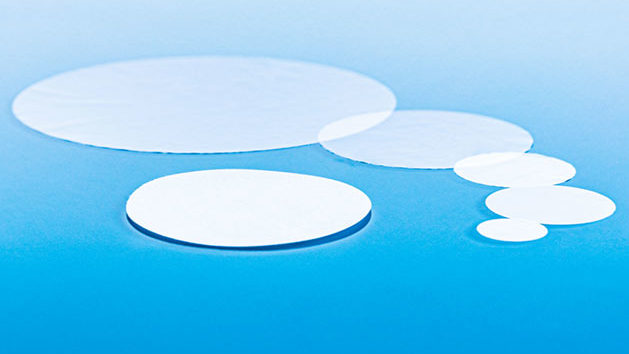

OxyDisc® Die-Cut Membrane Discs

OxyDisc® die-cut membrane discs can be easily mounted and produced using either hydrophobic or hydrophilic membranes for a variety of filtration or venting application requirements.

Membrane Technologies Available

Technologies

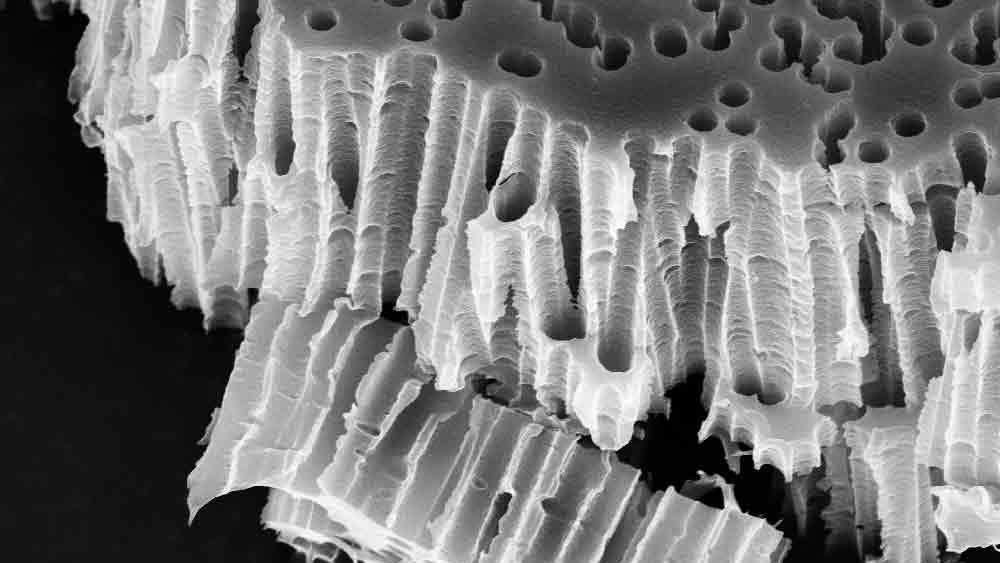

Unique-Mem® Unlaminated Track-Etched Membranes

Unique-Mem® unlaminated track-etched membranes, available as hydrophilic or hydrophobic, are characterized by cylindrical shaped pores penetrating the membrane in different angles. They have a smooth flat surface and well-defined flow rates.

Technologies

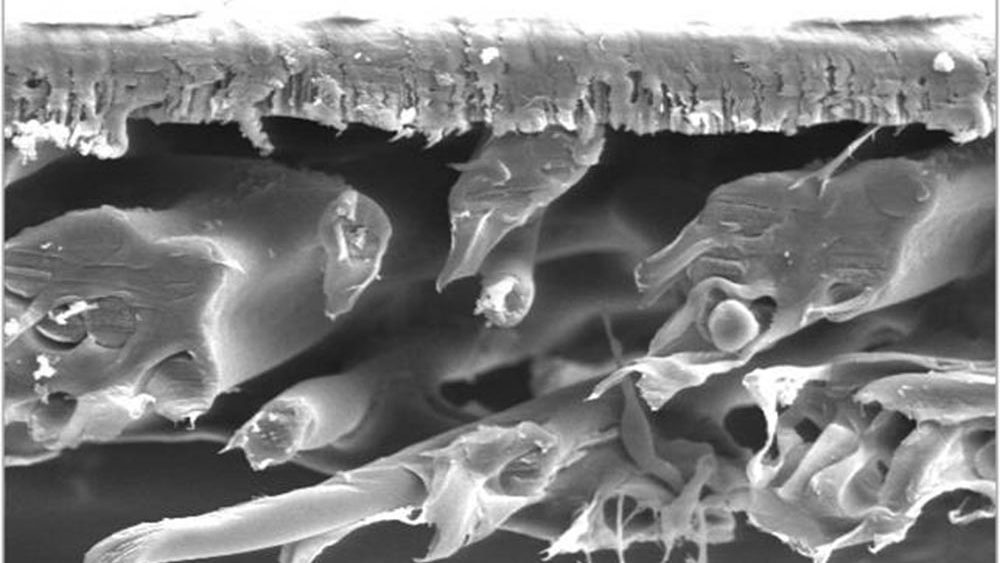

RoTrac® Laminated Track-Etched Membranes

RoTrac® laminated track-etched membranes are Unique-Mem® membranes that are supported with non-wovens (PP or PET) to create a more robust membrane. They are available as either hydrophilic or hydrophobic membranes.

Technologies

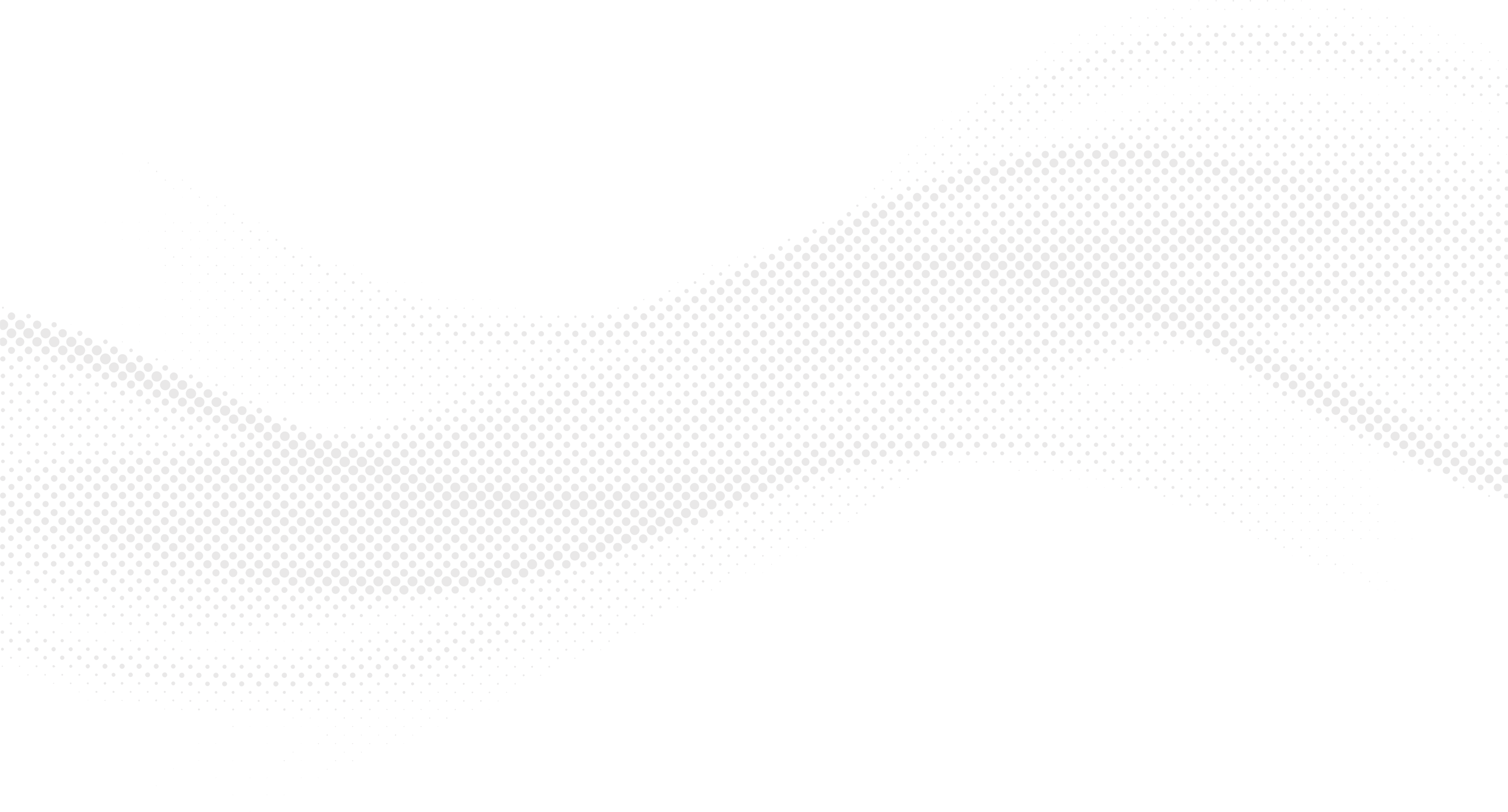

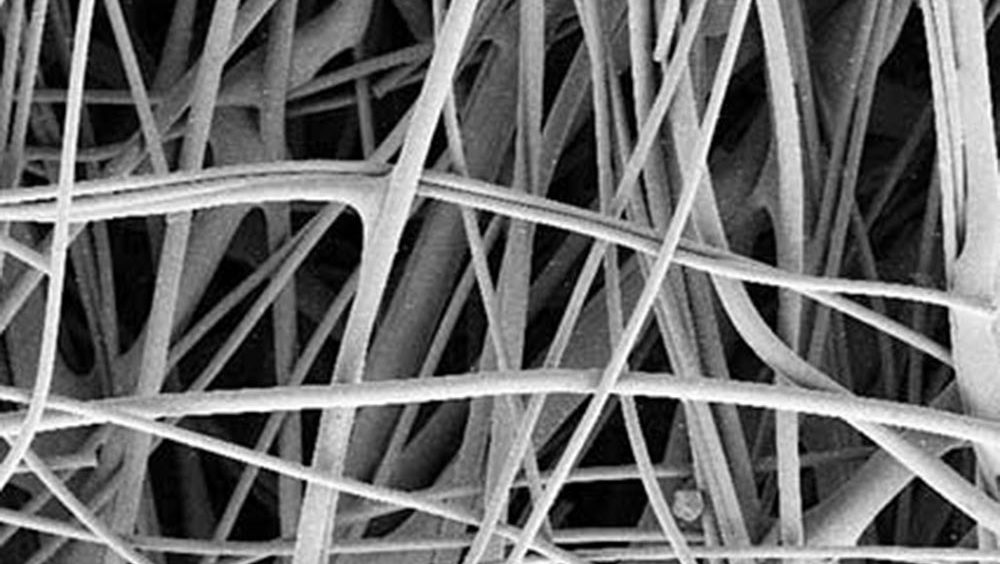

Fiber-Based Membranes

Fiber-based membranes are surface modified using a super-hydrophobic coating to repel water and other liquids while still allowing maximum airflow.

Contact Us

Would you like to speak to one of our nuclear track membrane experts?