Cell culturing is a key method used to isolate, analyze and grow human or animal cells under controlled conditions. While used in a variety of applications, cell culturing is heavily applied in biochemical, molecular, and physiological studies of metabolism and drug testing. Cell culturing helps understand how monoclonal antibodies, vaccines and therapeutic proteins interact with other chemicals for therapeutic studies.

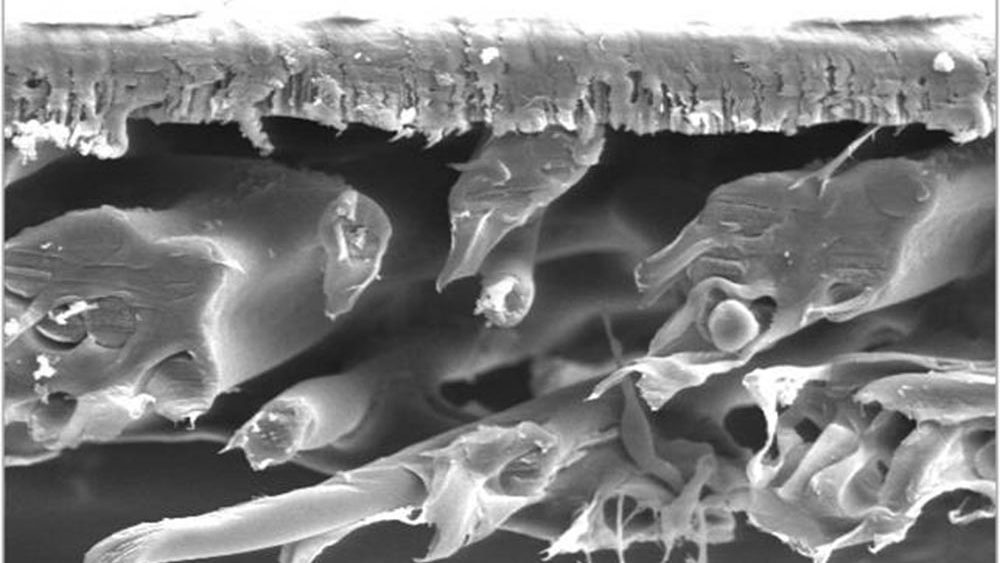

Our cell culture inserts can be manufactured with a variety of Unique-Mem® track-etched membranes and are bonded directly to the insert. The combination of the membrane sealing process with the Unique-Mem® membrane creates a strong bond between the plastic body and a perfectly smooth membrane surface, usable even for large inserts and in unique larger cell culture formats like rectangular or round versions with growth areas of up to 100 cm2 or even larger.

Oxyphen track-etched membranes are a perfect fit for this application, given the highly controlled membrane performance parameters, the wide variability in membrane thickness and pore size to regulate the nutrient media transport to the cells that facilitates the correct growth. When combined with our membrane assembly processes, customers can choose from a variety of cell culture inserts based on either a standard hanging design for three well sizes (6-, 12- and 24-well inserts) or a customized design per customer-specific requirements.

For cell culturing, applications such as co-culture, secretion, cytotoxicity studies and drug transport research, smaller pore sizes are recommended (~ 0.4µm – 1.0µm). Pore sizes from 3.0µm up to 8.0µm are suggested for chemotactic studies and/or migration, invasion. The thicknesses of the membranes range from 8 µm to 23 µm. More specific technical information is found below.

Related Resources

Viral Filtration Efficiency (VFE) Certificate

Final test report from Nelson Labs for Viral Filtration Efficiency (VFE) at an Increased Challenge Level. Also available is the Bacterial Filtration Efficiency (BFE) report.

Bacterial Filtration Efficiency (BFE) Certificate

Final test report from Nelson Labs for Bacterial Filtration Efficiency (BFE) at an Increased Challenge Level. Also available is the Viral Filtration Efficiency (VFE) report.

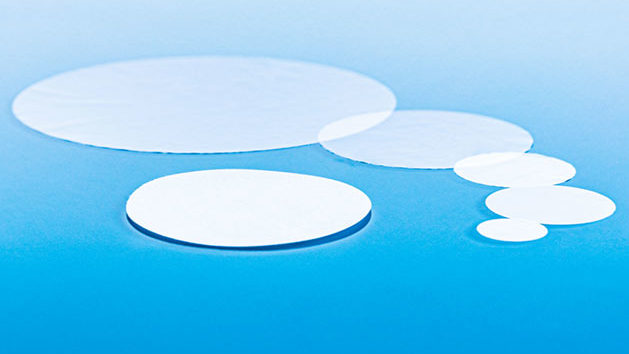

OxyDisc® Product Brochure

Learn more about OxyDisc® die-cut membrane discs that can be produced using either hydrophobic or hydrophilic membranes and easily handled and mounted using multiple assembly options to suit a variety of industries.

Register for our On-Demand Webinar

Delivering Precision & Control: An Introduction to Track-Etched Membrane Technology

Related Products

OxyPad® Self-Adhesive Pads

OxyPad® membrane pads, which are easily integrated inside or outside your housing design, promote consistent pressure equalization and protection against water, dust, and other harmful particulates.

OxyDisc® Die-Cut Membrane Discs

OxyDisc® die-cut membrane discs can be easily mounted and produced using either hydrophobic or hydrophilic membranes for a variety of filtration or venting application requirements.

OxySeal® Pressure Compensation Units

OxySeal® pressure compensated venting plugs, which are available with hydrophobic or oleophobic treated membranes, can prevent the ingress of liquid, water, dust, dirt, salt, and other contaminants.

Membrane Technologies Available

Technologies

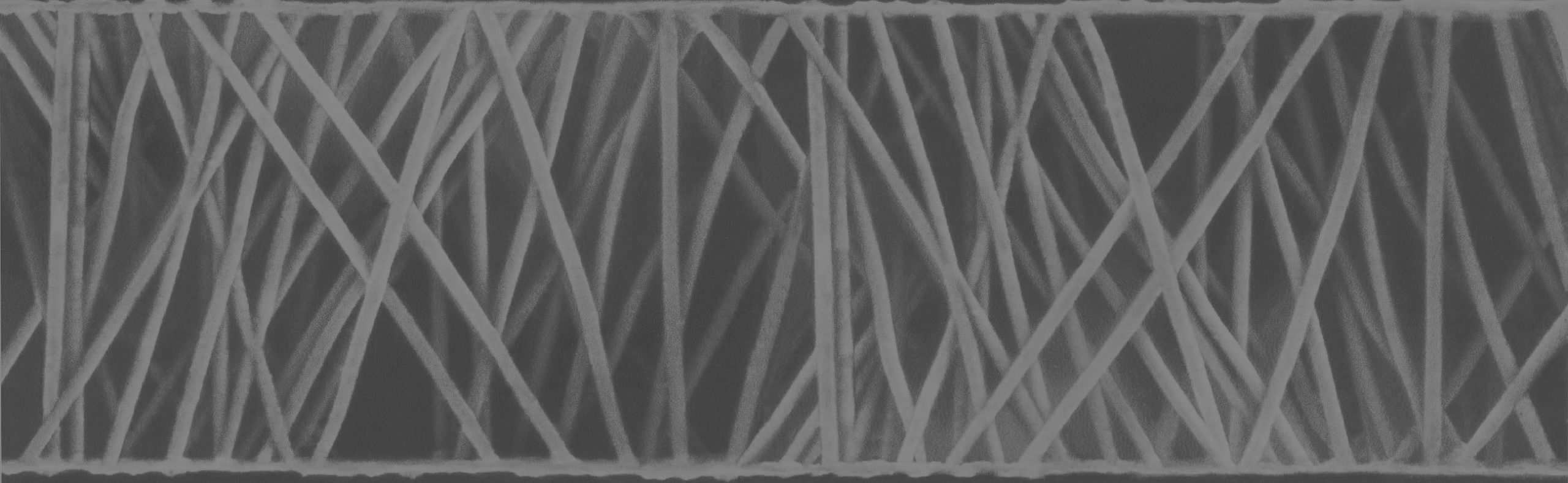

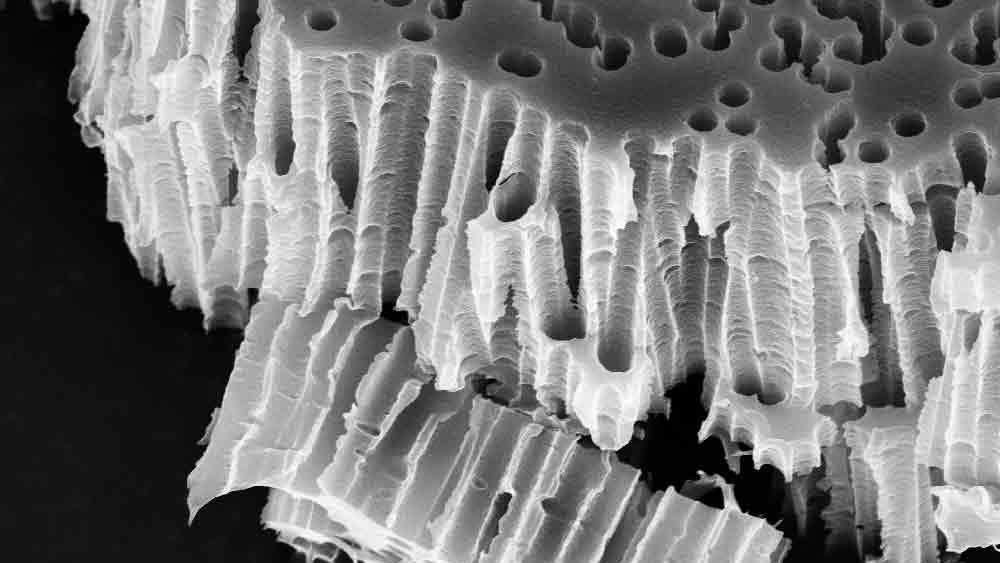

Unique-Mem® Unlaminated Track-Etched Membranes

Unique-Mem® track-etched membranes, available as hydrophilic or hydrophobic, are characterized by cylindrical shaped pores penetrating the membrane in different angles. They have a smooth flat surface and well-defined flow rates.

Technologies

RoTrac® Laminated Track-Etched Membranes

RoTrac® track-etched membranes are Unique-Mem® membranes that are supported with non-wovens (PP or PET) to create a more robust membrane. They are available as either hydrophilic or hydrophobic membranes.

Contact Us

Interested in speaking with one of our track-etched membrane experts?