To meet specific product solution requirements within the life science and automotive markets, Oxyphen engineers partner with leading OEMs to develop highly tailored components and assemblies for specific applications.

Using our fully automated 2K injection molding capabilities and long-term expertise in membrane welding and assembly technology, we serve as a one-stop shop, working with you through your design, prototyping, process planning, and product launch phases. From sensor venting and protection to headlight moisture control and cell-culture inserts, our track-etched membrane technology and partnership will pave the way to your cost-effective, high performing solution.

Highlighted Case Study

EV Battery Safety Vents

A manufacturer of electric vehicle (EV) lithium batteries reached out to us to develop and design a hydrophobic membrane that would meet their specifications as it relates to temperature stability, air flow, water entry pressure, and constant and reliable expansion properties.

Related Resources

RADAR Sensors Application Brochure

Learn more about Oxyphen’s track-etched membranes that serve as a multi-purpose venting solution – providing the adequate pressure compensation, durability, protection, and accuracy needed for reliable sensor accuracy and performance.

Viral Filtration Efficiency (VFE) Certificate

Final test report from Nelson Labs for Viral Filtration Efficiency (VFE) at an Increased Challenge Level. Also available is the Bacterial Filtration Efficiency (BFE) report.

Bacterial Filtration Efficiency (BFE) Certificate

Final test report from Nelson Labs for Bacterial Filtration Efficiency (BFE) at an Increased Challenge Level. Also available is the Viral Filtration Efficiency (VFE) report.

Register for our on-demand Webinar

For precision and control: An introduction to track-etched membrane technology

Related Products

Rollstock Membrane

Ideally suited for in-house and large-scale manufacturing applications, Oxyphen’s track-etched rollstock membrane can be laminated, unlaminated, or fiber-based – supplied from polyester (PET) or polycarbonate (PC) high quality raw materials.

OxyPad® Self-Adhesive Pads

OxyPad® membrane pads, which are easily integrated inside or outside your housing design, promote consistent pressure equalization and protection against water, dust, and other harmful particulates.

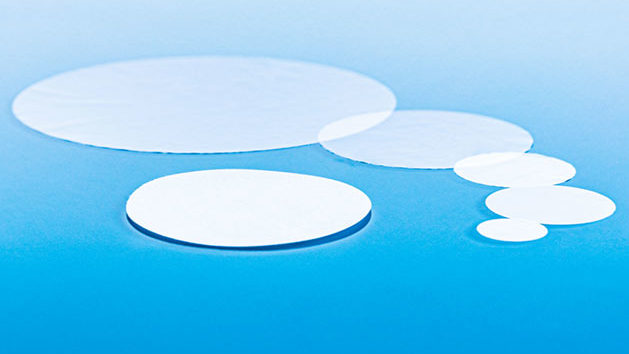

OxyDisc® Die-Cut Membrane Discs

OxyDisc® die-cut membrane discs can be easily mounted and produced using either hydrophobic or hydrophilic membranes for a variety of filtration or venting application requirements.

Membrane Technologies Available

Technologies

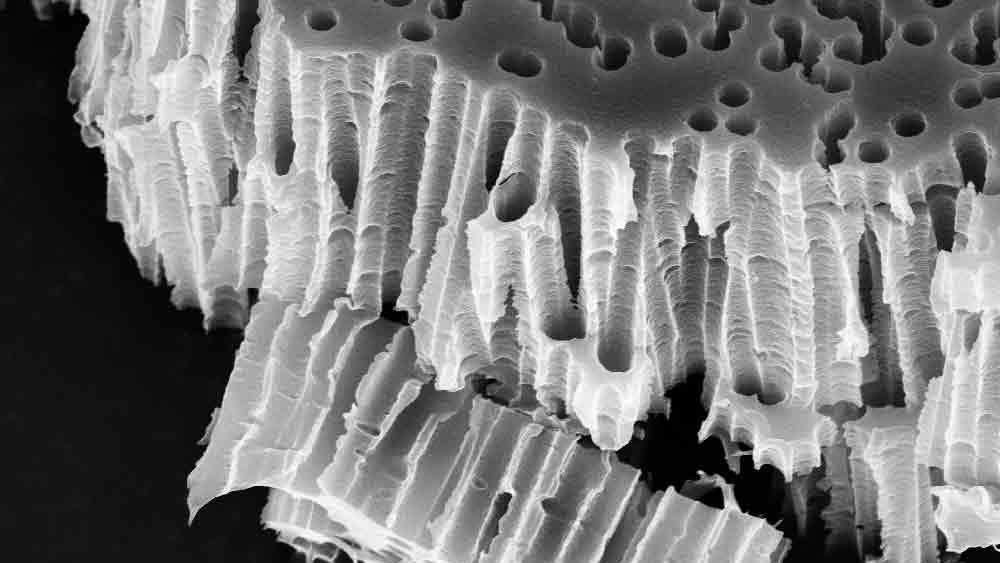

Unique-Mem® Unlaminated Track-Etched Membranes

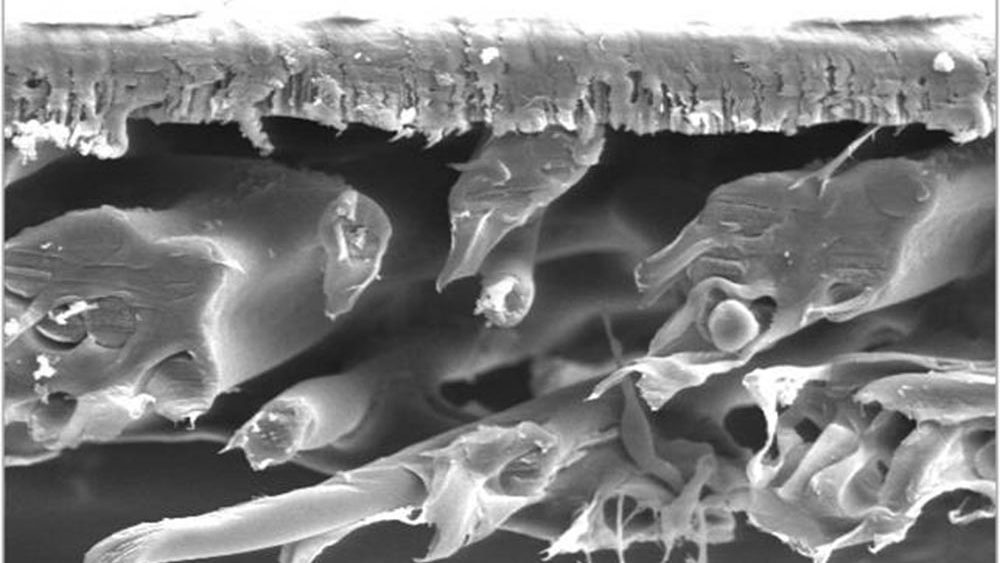

Unique-Mem® track-etched membranes, available as hydrophilic or hydrophobic, are characterized by cylindrical shaped pores penetrating the membrane in different angles. They have a smooth flat surface and well-defined flow rates.

Technologies

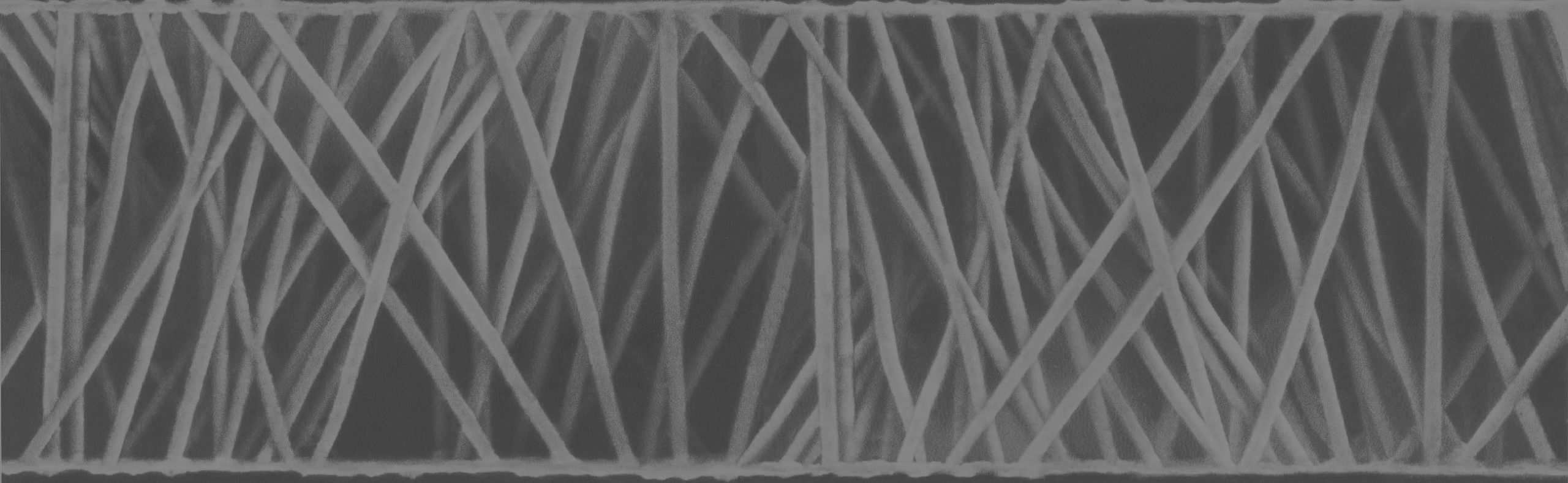

RoTrac® Laminated Track-Etched Membranes

RoTrac® track-etched membranes are Unique-Mem® membranes that are supported with non-wovens (PP or PET) to create a more robust membrane. They are available as either hydrophilic or hydrophobic membranes.

Technologies

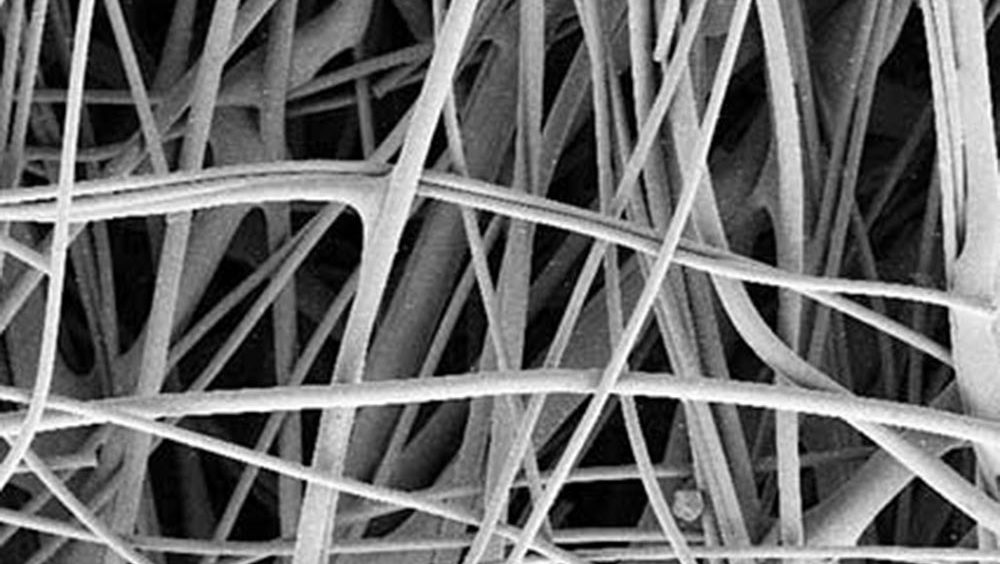

Fiber-Based Membranes

Fiber-based membranes are surface modified using a super-hydrophobic coating to repel water and other liquids while still allowing maximum airflow.

Contact Us

Would you like to speak to one of our nuclear track membrane experts?