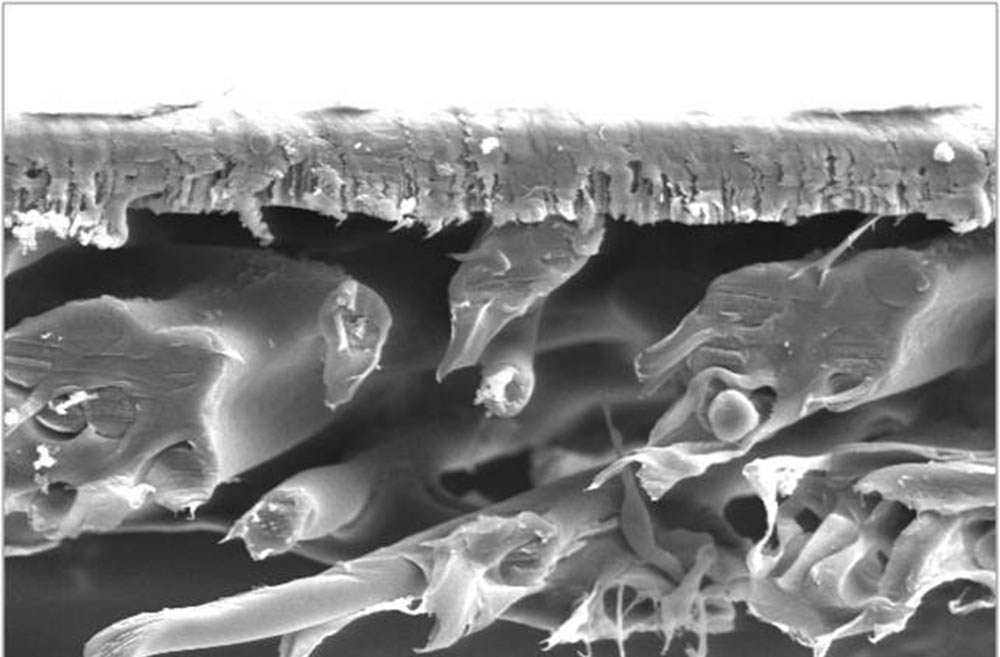

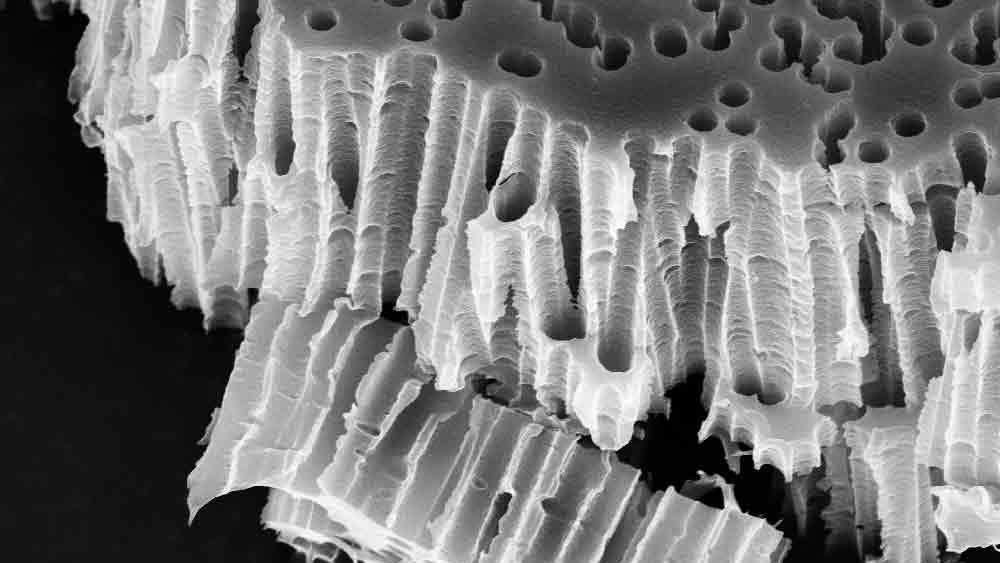

RoTrac®aminated track-etched membranes are based on Unique-Mem®Membrane technology – consisting of a single, unsupported PET or PC membrane layer – supplemented by an additional PP or PET nonwoven carrier layer. – Etched membranes are based on

The laminates are adhesive-free and are thermally bonded for easy cleaning. RoTrac® laminated membranes are available in various thicknesses and custom dimensions and can be treated with hydrophilic, hydrophobic, or oleophobic properties as required.

The laminates are adhesive-free and are manufactured by thermal bonding for easier cleaning. RoTrac® laminated membranes are available in various thicknesses and custom dimensions and can be treated with hydrophilic, hydrophobic, or oleophobic properties as required.

Alle Oxyphen-Membranen sind 100 % PFOA-frei und können gemäß der neuesten REACH-Verordnung ab dem 4. Juli 2020 bedenkenlos verwendet werden.

Highlighted Case Study

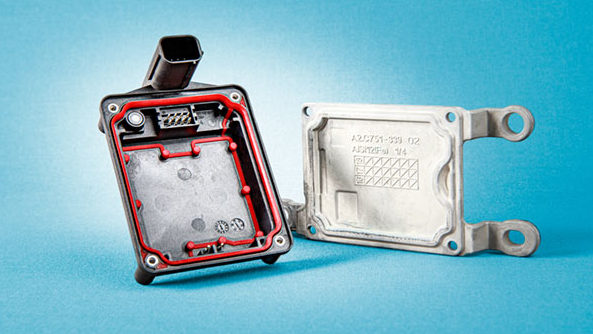

Ventilation of car headlights

A manufacturer of automotive lighting equipment approached Oxyphen to design and engineer a hydrophobic membrane venting solution that would address four key design challenges: ingress protection, sufficient airflow to avoid condensation, customized temperature conditions, and ease of installation.

Related Resources

Automotive Lighting Application Brochure

Learn more about Oxyphen’s ultra-hydrophobic fiber-based membrane vents that provide a high airflow while also preventing liquid, fine dust and particles, and humidity from entering the lighting system.

RADAR Sensors Application Brochure

Learn more about Oxyphen’s track-etched membranes that serve as a multi-purpose venting solution – providing the adequate pressure compensation, durability, protection, and accuracy needed for reliable sensor accuracy and performance.

EV Battery Safety Vents Application Brochure

Learn more about Oxyphen’s hydrophobic all-in-one solution that protects critical internal components from the ingress of liquid, dust, dirt, and other contaminants while also having the ability to burst at predefined overpressures to prevent potential explosions from taking place in the event of thermal runaway.

Register for our on-demand Webinar

For precision and control: An introduction to track-etched membrane technology

Related Products

Rollstock Membrane

Ideally suited for in-house and large-scale manufacturing applications, Oxyphen’s track-etched Rollstock membrane can be laminated, unlaminated, or fiber-based – supplied from polyester (PET) or polycarbonate (PC) high quality raw materials.

OxyPad® Self-Adhesive Pads

OxyPad® membrane pads, which are easily integrated inside or outside your housing design, promote consistent pressure equalization and protection against water, dust, and other harmful particulates.

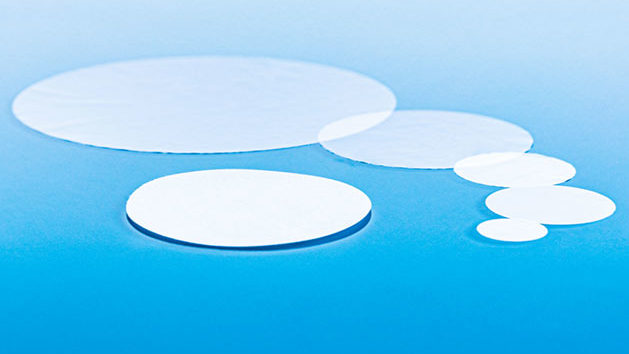

OxyDisc® Die-Cut Membrane Discs

OxyDisc® die-cut membrane discs can be easily mounted and produced using either hydrophobic or hydrophilic membranes for a variety of filtration or venting application requirements.

OxySeal® Pressure Compensation Units

OxySeal® pressure compensated venting plugs, which are available with hydrophobic or oleophobic treated membranes, can prevent the ingress of liquid, water, dust, dirt, salt, and other contaminants.

Assemblies & Modules

To meet specific product solution requirements within the life-science and automotive spaces, Oxyphen partner with leading OEMs to develop highly tailored components and assemblies for specific applications.

Customized Solutions

Oxyphen consists of a team of scientists, problem solvers, engineers, and strategic thinkers who are passionate about creating high-value solutions that bring customer’s product designs or concepts to life.

Other Membrane Technologies

Technologies

Unique-Mem® Unlaminated Track-Etched Membranes

Unique-Mem® track-etched membranes, available as hydrophilic or hydrophobic, are characterized by cylindrical shaped pores penetrating the membrane in different angles. They have a smooth flat surface and well-defined flow rates.

Technologies

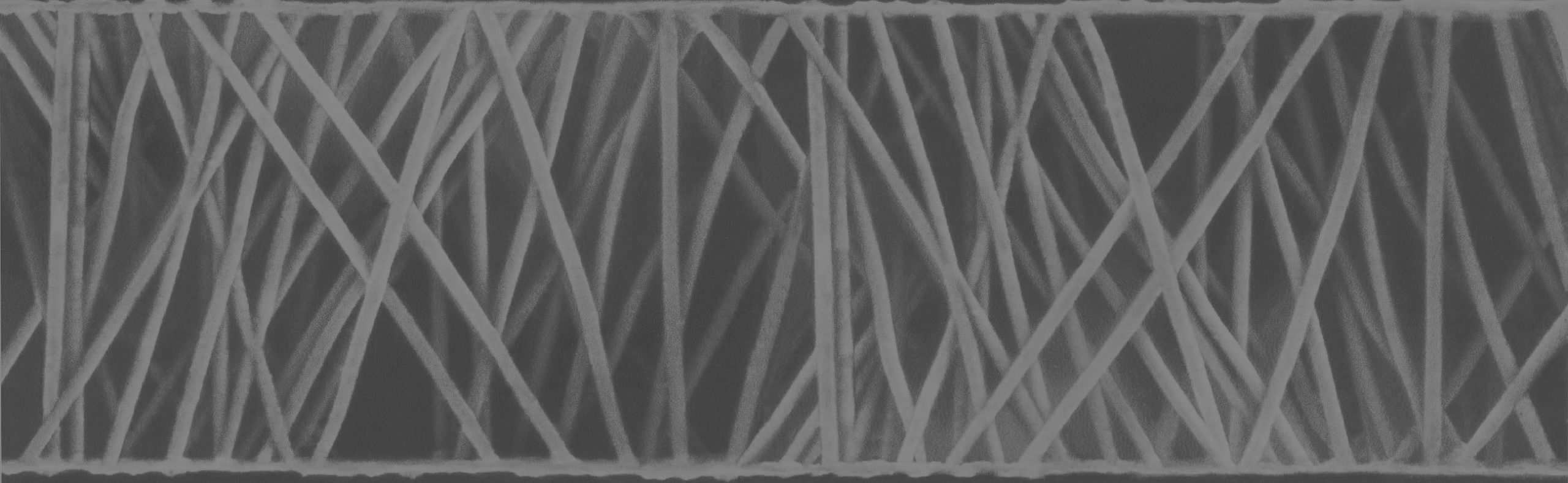

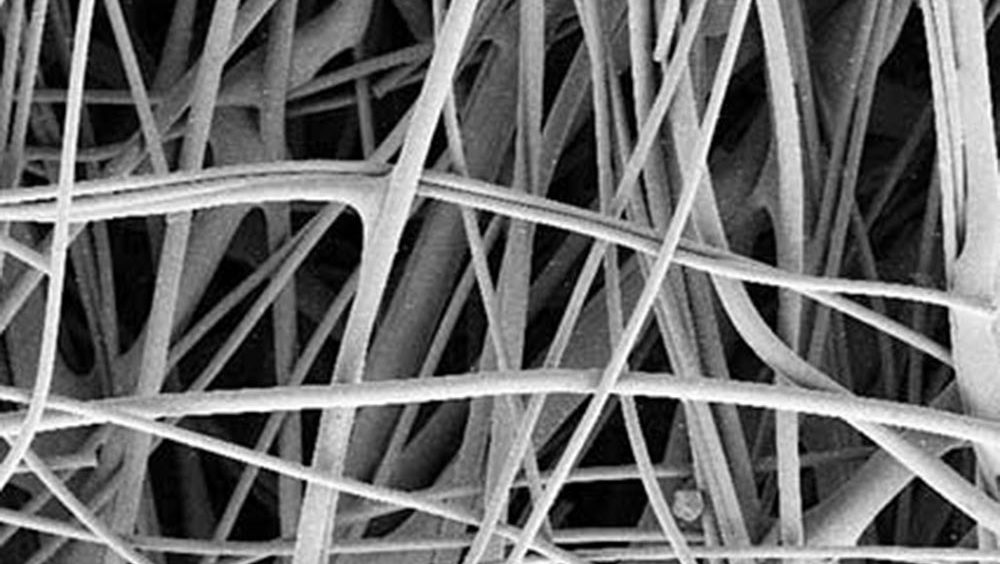

Fiber-Based Membranes

Fiber-based membranes are surface modified using a super-hydrophobic coating to repel water and other liquids while still allowing maximum airflow.

Contact Us

Would you like to speak to one of our nuclear track membrane experts?