Personal care devices such as electric toothbrushes, shavers or epilators are often used under humid or wet conditions. To ensure continued functioning of the device, Oxyphen’s track-etched membrane solutions provide protection against water and other contaminant media. In addition, they are designed for dependable pressure equalization when heat and off-gassing occur from batteries during operation. This can help to avoid potentially dangerous over-pressurization within the device that can lead to premature failure.

Related Resources

OxyDisc® Product Brochure

Learn more about OxyDisc® die-cut membrane discs that can be produced using either hydrophobic or hydrophilic membranes and easily handled and mounted using multiple assembly options to suit a variety of industries.

OxySeal® Product Brochure

Learn more about OxySeal® pressure compensation units that are designed to be a plug & play solution for easy integration into existing product assemblies while protecting from any environmental impact.

OxyPad® Product Brochure

Learn more about OxyPad® 100% PFOA-free hydrophobic and oleophobic-treated self-adhesive pads that provide consistent pressure equalization to reduce seal stress, minimize condensation, and protect the housing.

Register for our on-demand Webinar

For precision and control: An introduction to track-etched membrane technology

Related Products

OxyPad® Self-Adhesive Pads

OxyPad® membrane pads, which are easily integrated inside or outside your housing design, promote consistent pressure equalization and protection against water, dust, and other harmful particulates.

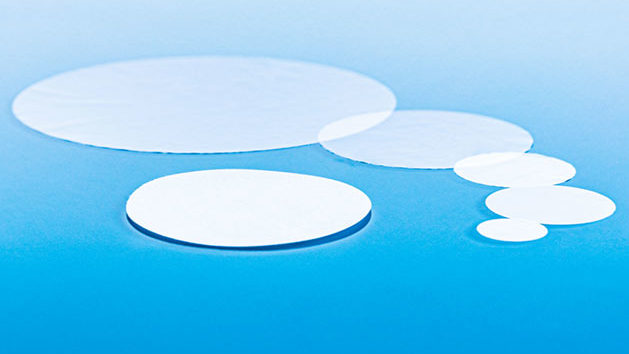

OxyDisc® Die-Cut Membrane Discs

OxyDisc® die-cut membrane discs can be easily mounted and produced using either hydrophobic or hydrophilic membranes for a variety of filtration or venting application requirements.

OxySeal® Pressure Compensation Units

OxySeal® pressure compensated venting plugs, which are available with hydrophobic or oleophobic treated membranes, can prevent the ingress of liquid, water, dust, dirt, salt, and other contaminants.

Membrane Technologies Available

Technologies

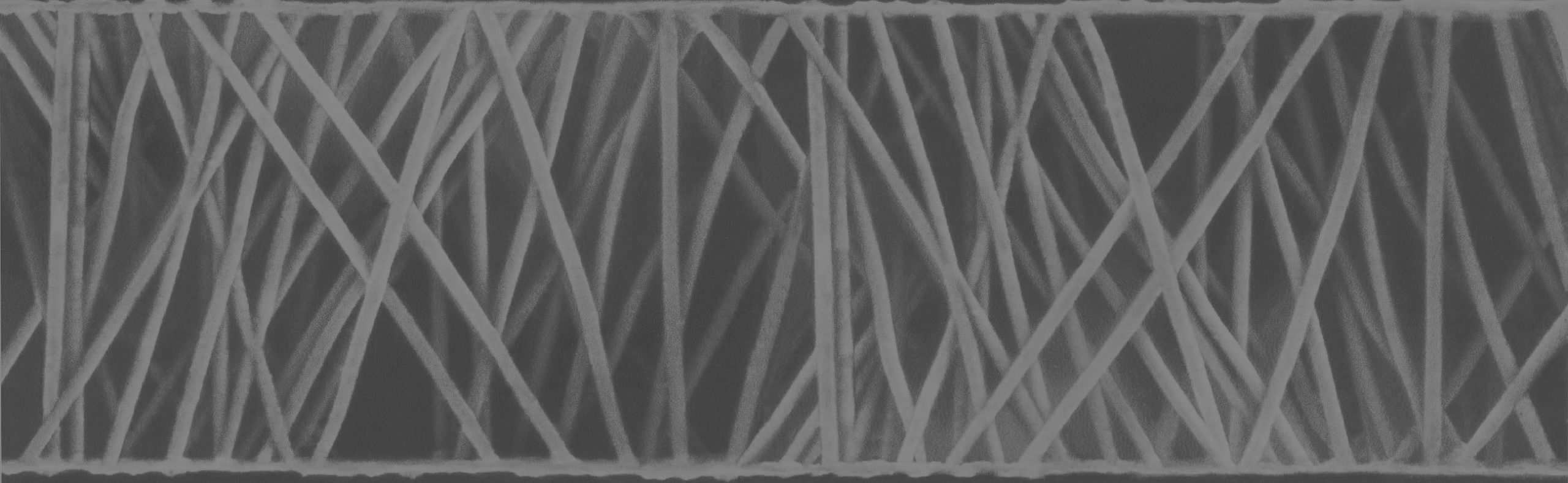

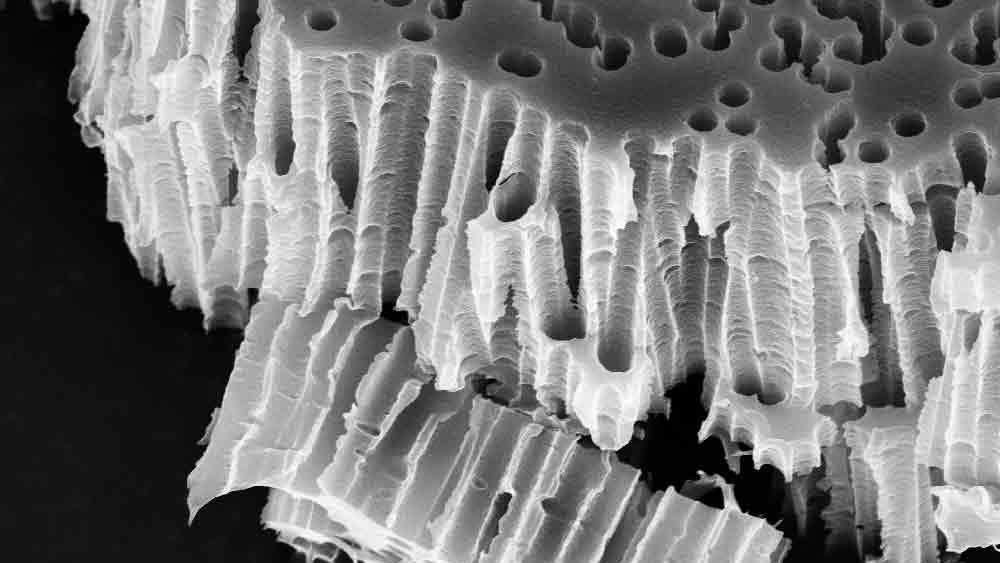

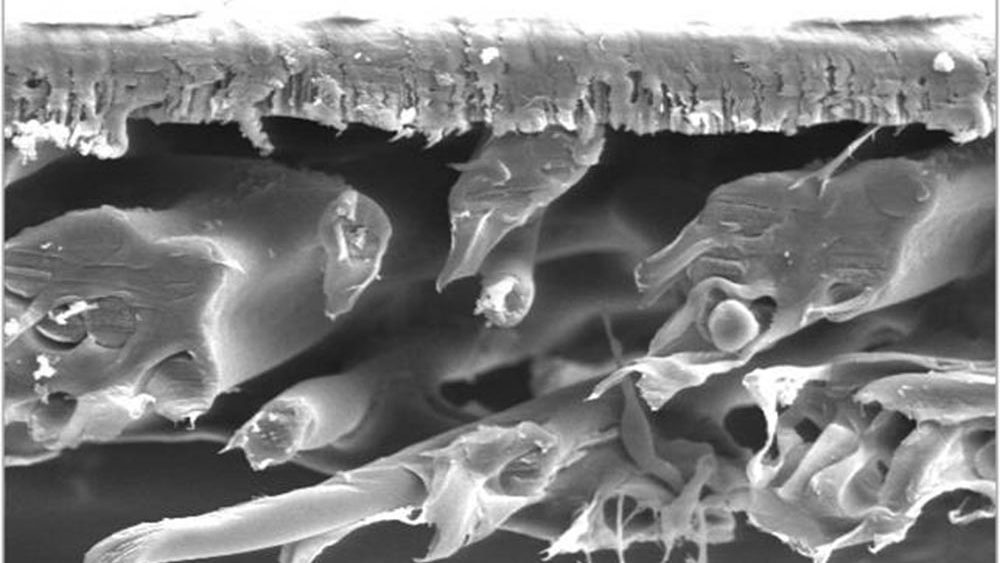

Unique-Mem® Unlaminated Track-Etched Membranes

Unique-Mem® track-etched membranes, available as hydrophilic or hydrophobic, are characterized by cylindrical shaped pores penetrating the membrane in different angles. They have a smooth flat surface and well-defined flow rates.

Technologies

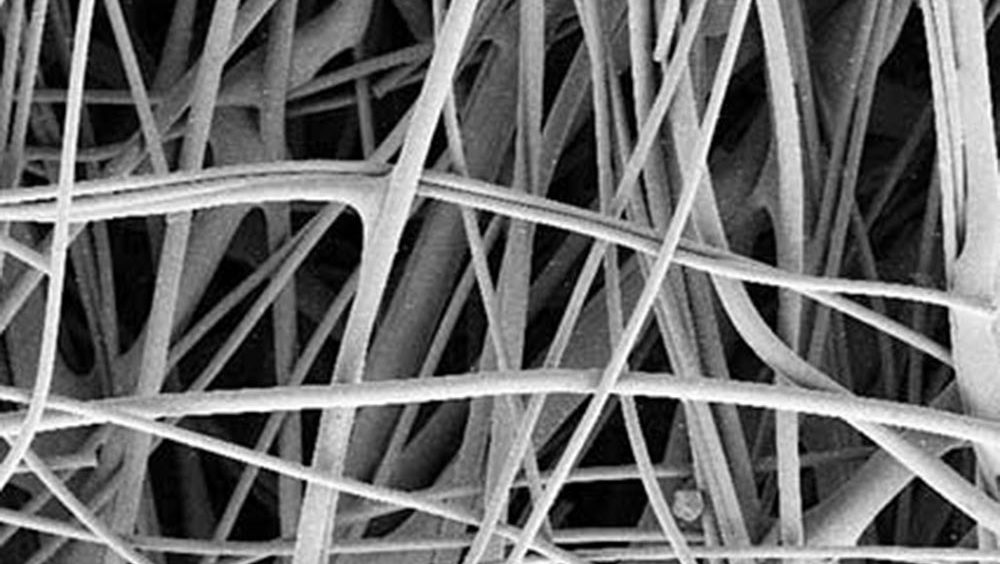

RoTrac® Laminated Track-Etched Membranes

RoTrac® track-etched membranes are Unique-Mem® membranes that are supported with non-wovens (PP or PET) to create a more robust membrane. They are available as either hydrophilic or hydrophobic membranes.

Technologies

Fiber-Based Membranes

Fiber-based membranes are surface modified using a super-hydrophobic coating to repel water and other liquids while still allowing maximum airflow.

Contact Us

Would you like to speak to one of our nuclear track membrane experts?