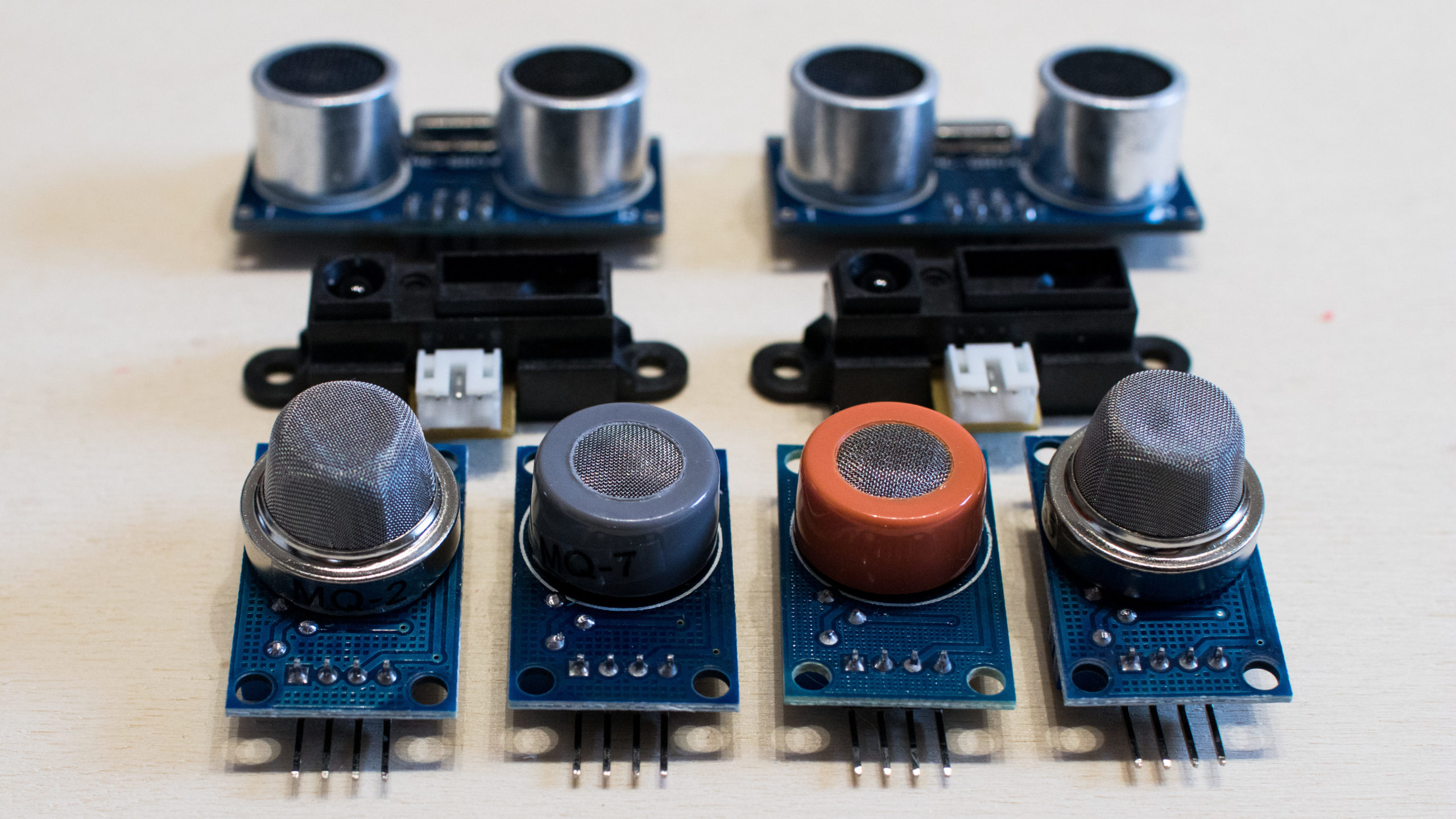

Increasing requirements in air quality as well as the rising industrial safety demands are driving the need for gas sensor technology that performs reliably, accurately, and for longer lifespans. Whether these be wearables, smart home applications, or industrial applications such as power generation or chemical facilities, a key performance driver of these gas sensors is the track-etched membrane technology which can facilitate faster detection, pressure equalization, and protection against contaminants. Oxyphen utilizes decades of experience to supply track-etched membrane technology with the broadest range of pore sizes and distributions – all while offering the lowest tolerances on the market.

Our unique membranes offer distinct advantages over mechanical vents or physical openings, since intrusion of dust and moisture can be avoided and there are no moving parts that can stick or only work in one direction. Unlike competing track-etched technology, Oxyphen’s membranes will not have affinity to shrinkage or deformation and can withstand temperature fluctuations as well as exposure to most chemicals.

When manufacturers partner with Oxyphen, they can be assured of receiving a consistent membrane permeability that is 100% quality controlled, free of PFOA ingredients, and per their specific application’s pore size, air flow rate, adhesion level, and material requirements.

We look forward to partnering with you on new opportunities – from the conceptual phase to the product launch – so that we can bring your next-generation sensor product to life.

Related Resources

OxyDisc® Product Brochure

Learn more about OxyDisc® die-cut membrane discs that can be produced using either hydrophobic or hydrophilic membranes and easily handled and mounted using multiple assembly options to suit a variety of industries.

OxySeal® Product Brochure

Learn more about OxySeal® pressure compensation units that are designed to be a plug & play solution for easy integration into existing product assemblies while protecting from any environmental impact.

OxyPad® Product Brochure

Learn more about OxyPad® 100% PFOA-free hydrophobic and oleophobic-treated self-adhesive pads that provide consistent pressure equalization to reduce seal stress, minimize condensation, and protect the housing.

Register for our on-demand Webinar

For precision and control: An introduction to track-etched membrane technology

Related Products

OxyPad® Self-Adhesive Pads

OxyPad® membrane pads, which are easily integrated inside or outside your housing design, promote consistent pressure equalization and protection against water, dust, and other harmful particulates.

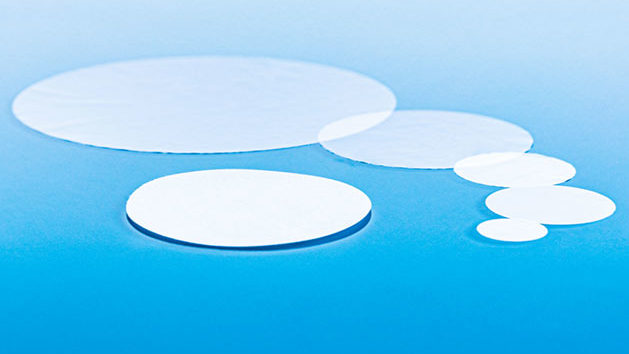

OxyDisc® Die-Cut Membrane Discs

OxyDisc® die-cut membrane discs can be easily mounted and produced using either hydrophobic or hydrophilic membranes for a variety of filtration or venting application requirements.

OxySeal® Pressure Compensation Units

OxySeal® pressure compensated venting plugs, which are available with hydrophobic or oleophobic treated membranes, can prevent the ingress of liquid, water, dust, dirt, salt, and other contaminants.

Membrane Technologies Available

Technologies

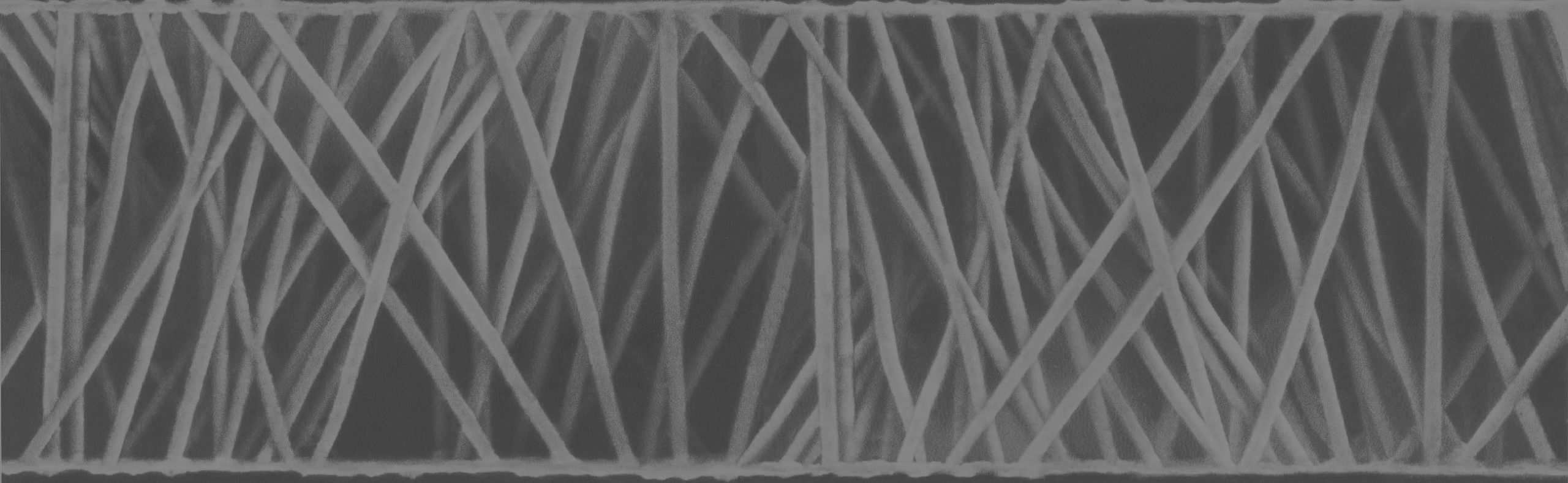

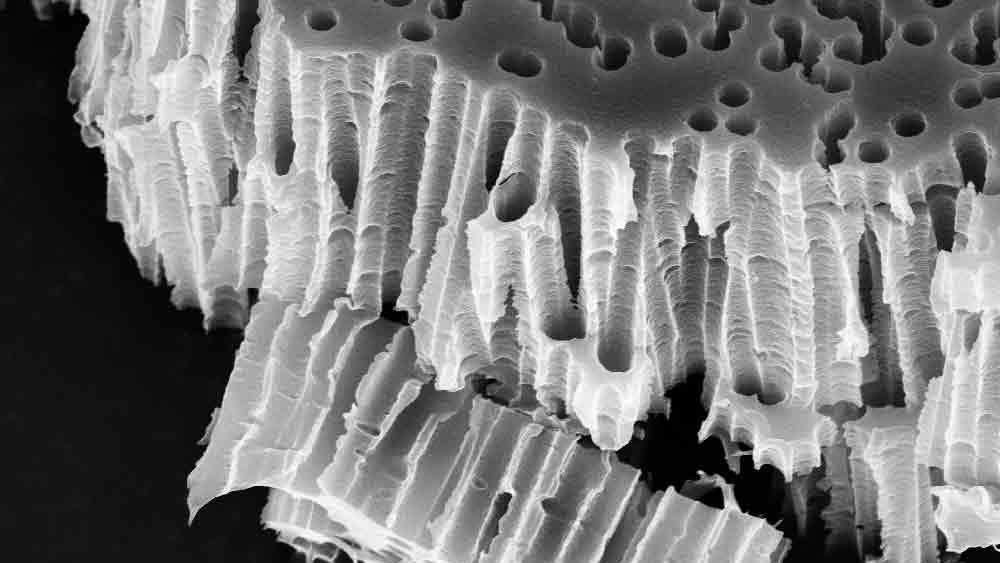

Unique-Mem® Unlaminated Track-Etched Membranes

Unique-Mem® track-etched membranes, available as hydrophilic or hydrophobic, are characterized by cylindrical shaped pores penetrating the membrane in different angles. They have a smooth flat surface and well-defined flow rates.

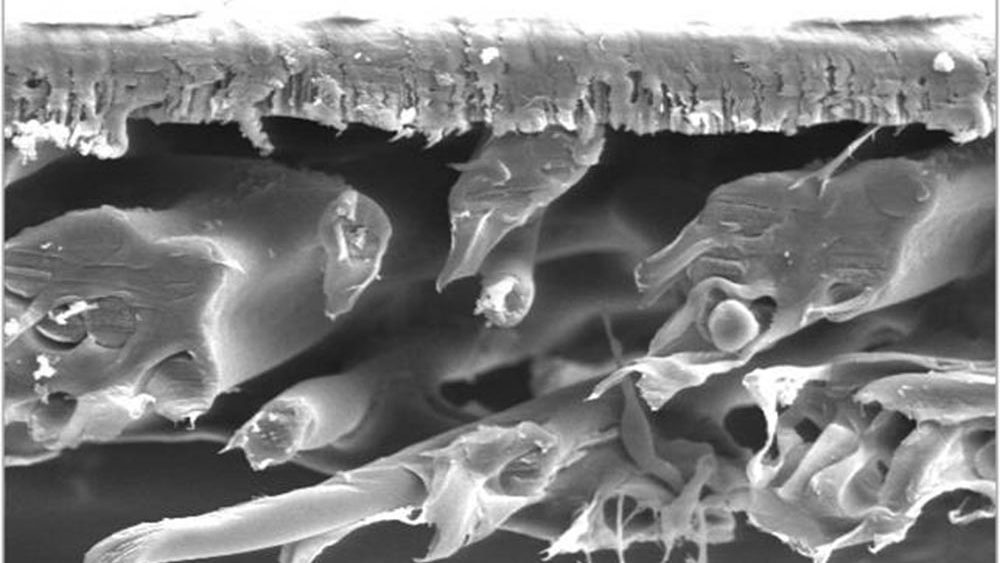

Technologies

RoTrac® Laminated Track-Etched Membranes

RoTrac® track-etched membranes are Unique-Mem® membranes that are supported with non-wovens (PP or PET) to create a more robust membrane. They are available as either hydrophilic or hydrophobic membranes.

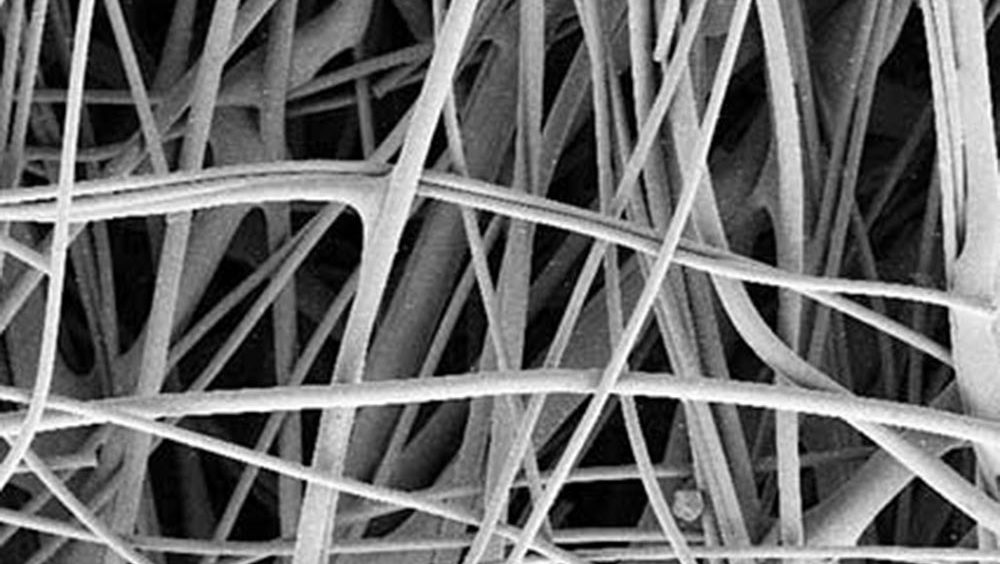

Technologies

Fiber-Based Membranes

Fiber-based membranes are surface modified using a super-hydrophobic coating to repel water and other liquids while still allowing maximum airflow.

Contact Us

Would you like to speak to one of our nuclear track membrane experts?