Clean Room

The production area of Oxyphen is highly clean and controlled. Regular cleaning schedules and careful cleaning of the production equipment prior to usage ensures the highest quality of Oxyphen track-etched membranes. High purity and diligent care for our membrane is the heart of the Oxyphen production processes. For dedicated products with requirements exceeding the high purity standard of the common Oxyphen production area, a Class 7 Clean Room was established. Within this environment, the membrane can be processed into various products like disks, cell culture inserts or other assembled parts.

Sterilization

Oxyphen’s track-etched PET membrane is a versatile material that supports various methods of sterilization. Standard procedures like autoclave and EtO sterilization can be easily implemented along with radiation-based sterilization techniques like x-ray, gamma or e-beam. Our PET membranes, available as single units or up to whole pallets, are radiation durable, unlike other materials like PTFE and PVDF.

Available Methods:

- EtO

- E-Beam

- Gamma

- Autoclave

Injection Molding and Automated Assembly

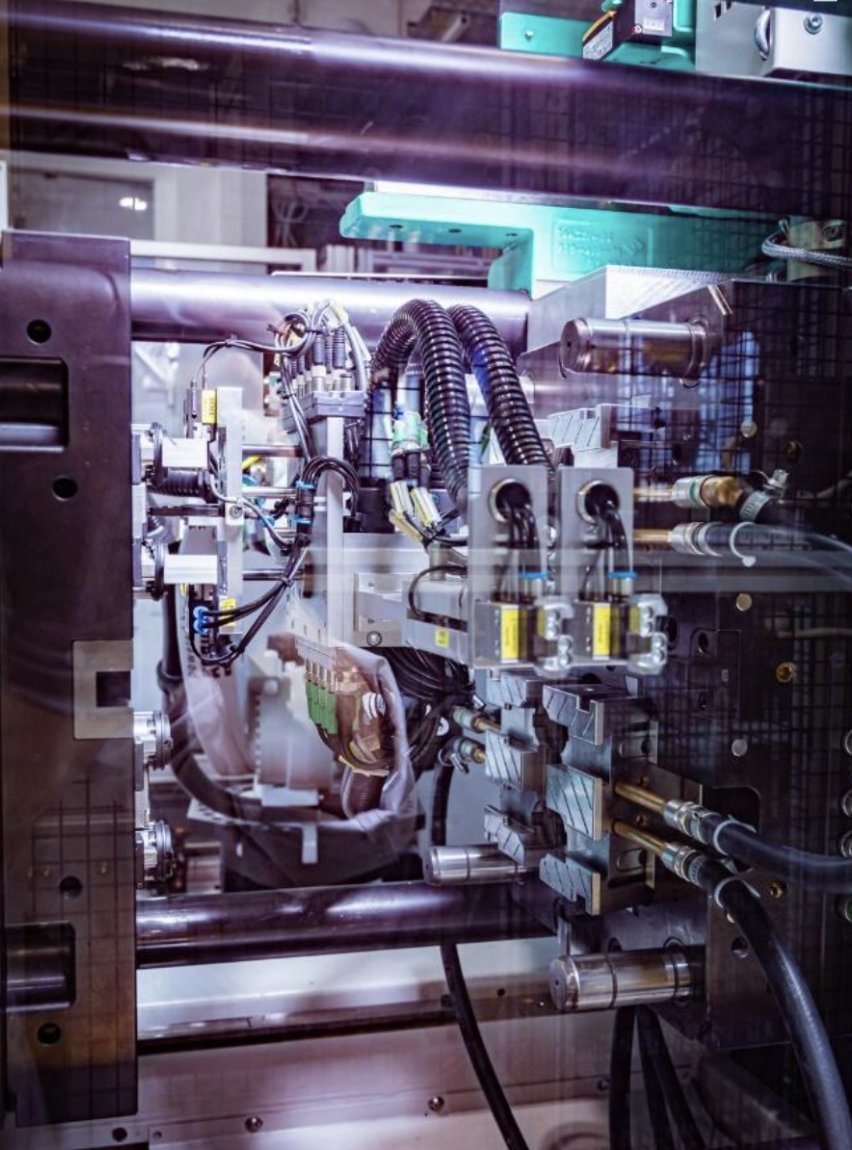

In our ISO 9001:2015 and IATF 16949 certified manufacturing facility, we ensure a flawless and process-controlled production of injection molding parts and assemblies using state-of-the-art machinery from ARBURG.

With a range from 400-1500 kN clamping force, all machines are fully automized with individual peripheral technology, robots and pickers including a fully automated turnkey production unit for 2K injection molding parts or assemblies.

Machine park:

Several Arburg 270 C 400-70

Arburg 370 C 700-100

Arburg 470 C 1500-400

Arburg 2K 470 S 1100-170/30

Materials use:

TPE, TPV, TPE-Blend, PS, PC/ABS, POM, PP

and others according to customer requirements

Together with our customers (from the automotive and life-science industries), we develop components and assemblies for specific applications. This could include plug-in solutions for housings, sensor venting, protection for automotive headlight moisture control as well as cell culture inserts.

OxySeal® pressure compensation units can be considered as a plug & play solution. Each unit consists of a hydrophobic track-etched membrane that has been injection-molded with a thermoplastic elastomer seal. This accounts for a tight fit inside the compartments opening without the need for additional anchor or fasteners.

OxySeal® units are flexible in design and can be drafted to specific customer needs. From molding dimensions, shapes, and resins across to the membrane’s properties. We are capable of manufacturing tailored solutions without any design compromises.

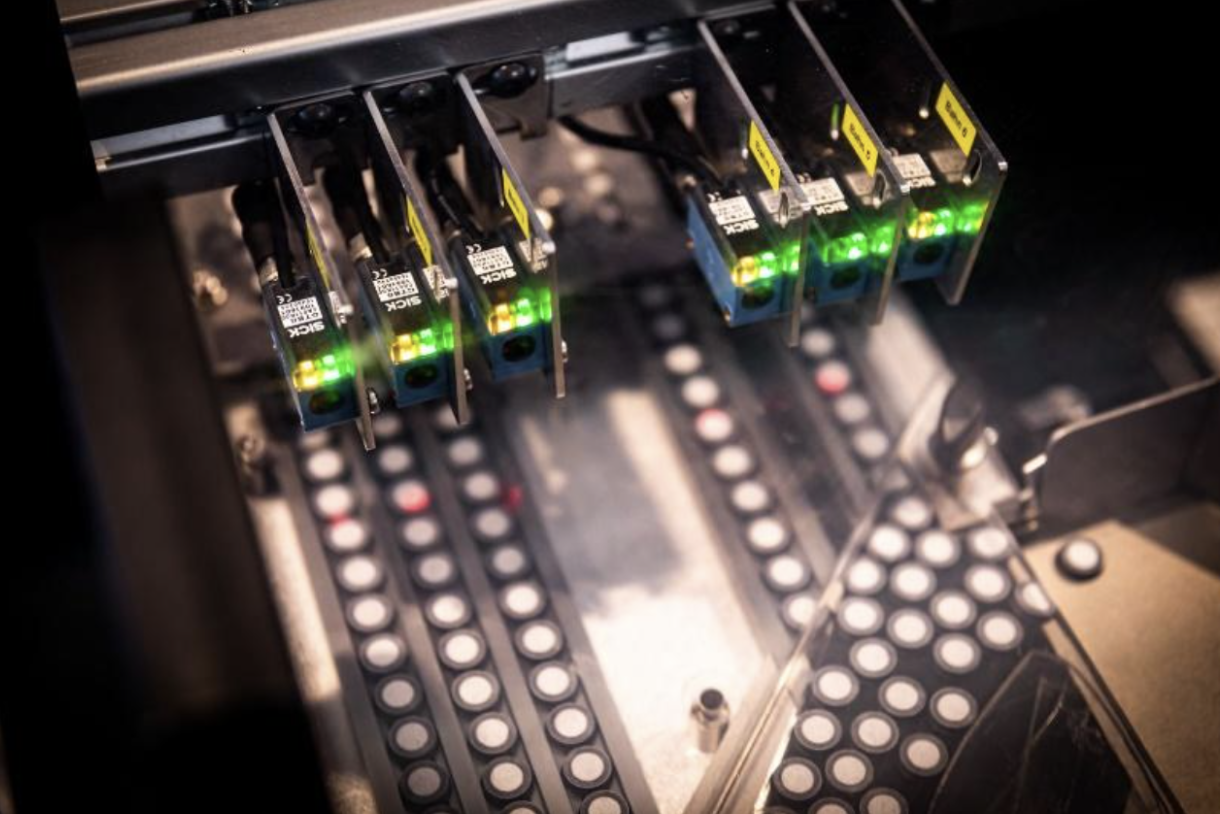

Customer satisfaction is our top priority; therefore, we established a 100% optical quality inspection for all plug-in vent product solutions. By using the latest technology and high-speed cameras, we can detect and remove pieces with even the slightest imperfections.

Next Generation Product Solutions

To reduce production time and resources, we began to implement fully automated production lines which fulfills our customer needs. Based on our proven track record and decades of experience, engineers from different industries rely on Oxyphen whenever they anticipate challenges in membrane assembly. Together, we determine the ideal membrane assembly for our production floors to pave the way for our customers next generation product solutions.

Contact Us

Interested in speaking with one of our track-etched membrane experts?