Porous membrane solutions designed for life science, industrial, and automotive applications provide an elevated level of precision and control due to their exceptional flexibility in tailoring pore size and density for your venting and filtration challenges.

When your application demands the highest precision in both pore size and density – in addition to an unparalleled level of customer service and application experience to help bring your innovation to life.

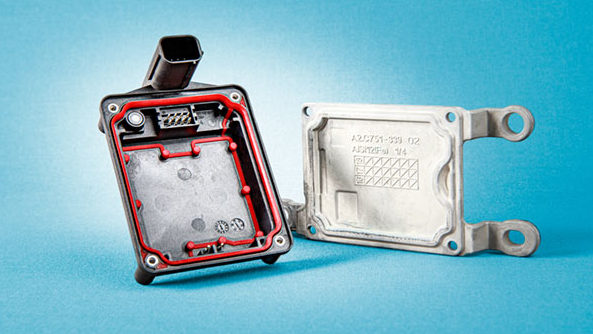

Hydrophobic or hyrophilic self-adhesive membrane pads on liner material. Easily integrated to promote consistent pressure equalization and protection against the ingress of water, dust, or other harmful particulates.

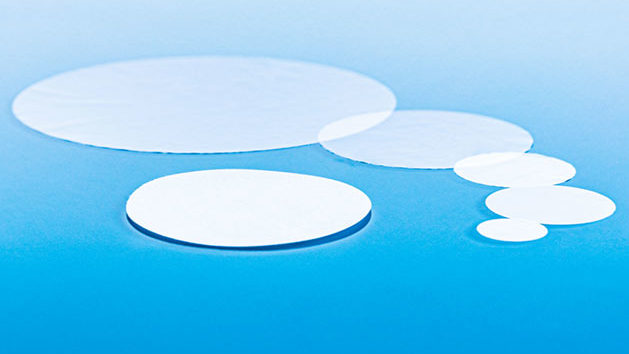

Pre-punched hydrophobic or hydrophilic membrane discs in various dimensions. Easily mounted and produced using either hydrophobic or hydrophilic membranes for any filtration or venting application.

Pressure compensation venting plugs with hydrophobic or oleophobic treated membranes. Easily deployed to prevent the ingress of oily liquids, water, dust, dirt, salts, or other contaminants. Can also be fully customizable.

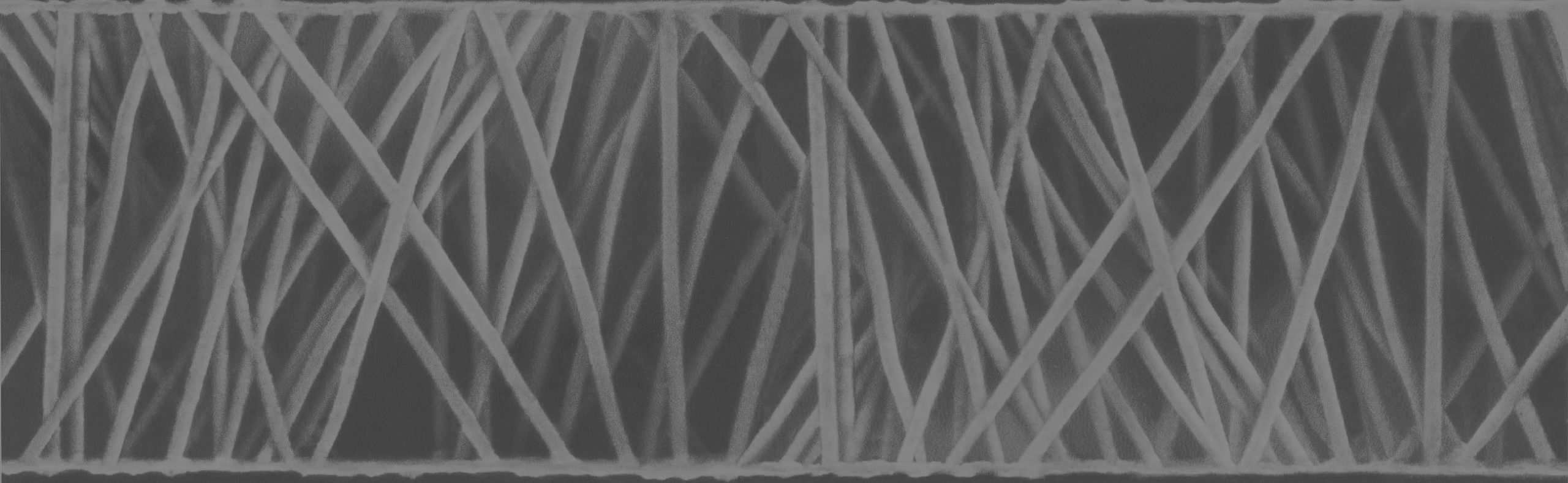

Track-etched rollstock membrane that can be laminated, unlaminated, or fiber-based, is supplied from polyester (PET) or polycarbonate (PC) high quality raw materials. Membranes can be treated with hydrophilic, hydrophobic, or oleophobic properties.

To meet specific product solution requirements within the life-science and automotive spaces, Oxyphen engineers partner with leading OEMs to develop highly tailored components and assemblies for specific applications.

As a team of scientists, problem solvers, engineers, and strategic thinkers, Oxyphen is passionate about partnering with our customers to create high-value solutions that bring their product design or concept to life.

Interested in speaking with one of our track-etched membrane experts?